ProCRYL MMA Binder

PROCRYL MMA Binder

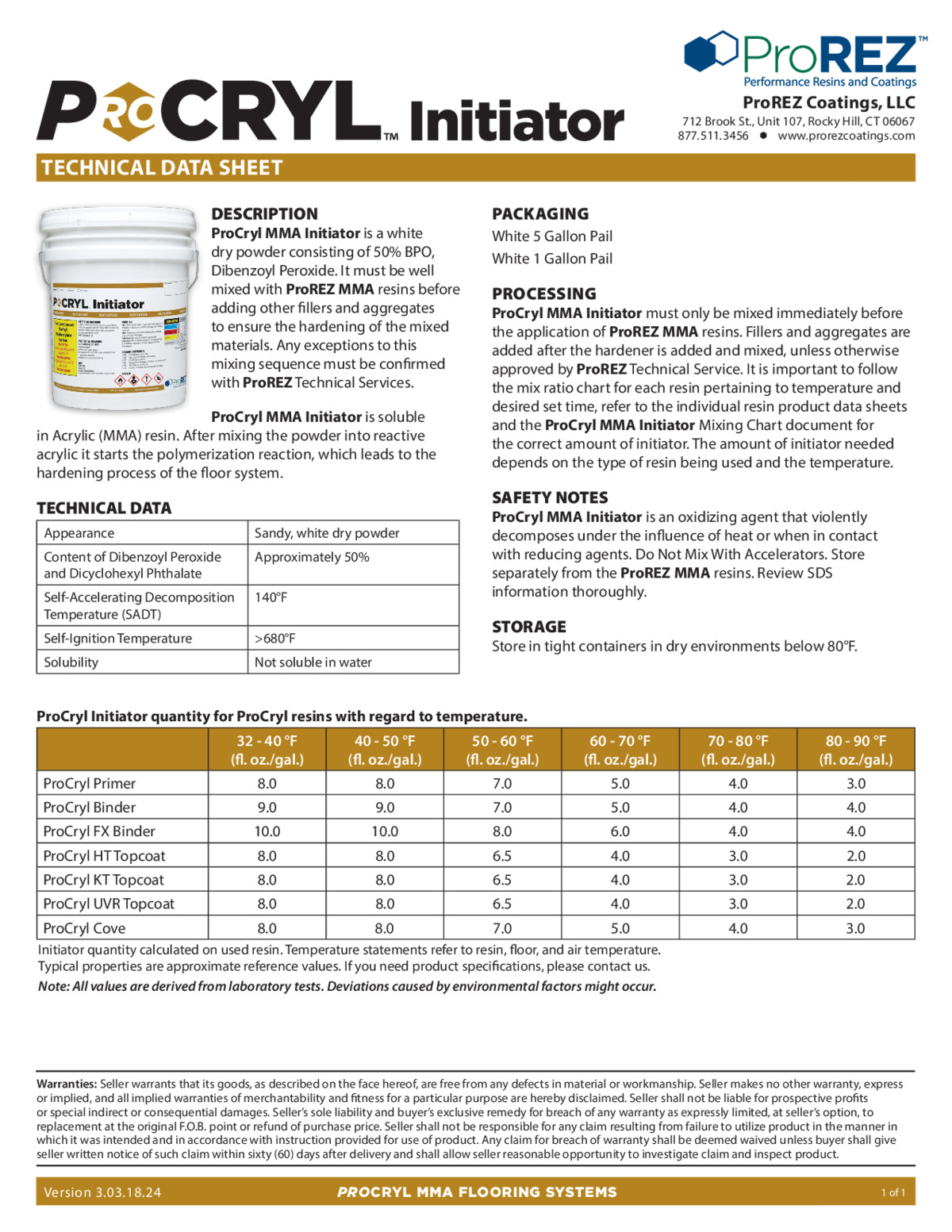

ProCryl MMA Binder is a high-build, 100% reactive methyl methacrylate resin used as the core bodycoat for self-leveling (SL), broadcast, and troweled mortar (TM) flooring systems within the ProREZ MMA line. When combined with ProCryl MMA Initiator, it cures rapidly—typically within 60 minutes—even in cold environments using ProCryl LTC catalyst. It provides excellent flow and leveling properties for resurfacing applications and is ideal for heavy-duty, hygienic environments such as food processing facilities, labs, commercial kitchens, and industrial floors exposed to mechanical wear.

The binder is designed for use with SL fillers or broadcast aggregates such as colored quartz or polymer flakes, and must always be installed over a properly primed surface using ProCryl MMA Primer. Application thickness should be no less than 65 mils per coat, followed by an appropriate MMA topcoat for full system integrity. VOC-compliant and adaptable across a wide temperature range, it supports both decorative and industrial flooring configurations with minimal downtime.