ProShield SL-60 and SL-100 are 100% solids, pigmented, high build coating systems for industrial and commercial settings. With the addition of ProFill SL, finely graded natural quartz aggregate and fillers to the ProPoxy SL resin, the SL-60 and SL-100 become excellent self-leveling (S/L) resurfacers. These high build epoxy options offer excellent versatility and durability in seamless floor protection. Their resin-rich designs make them a solid choice for higher impact and moderate to high traffic areas.

Contact Sales

View or download detailed information concerning this ProREZ system with the following PDF resources.

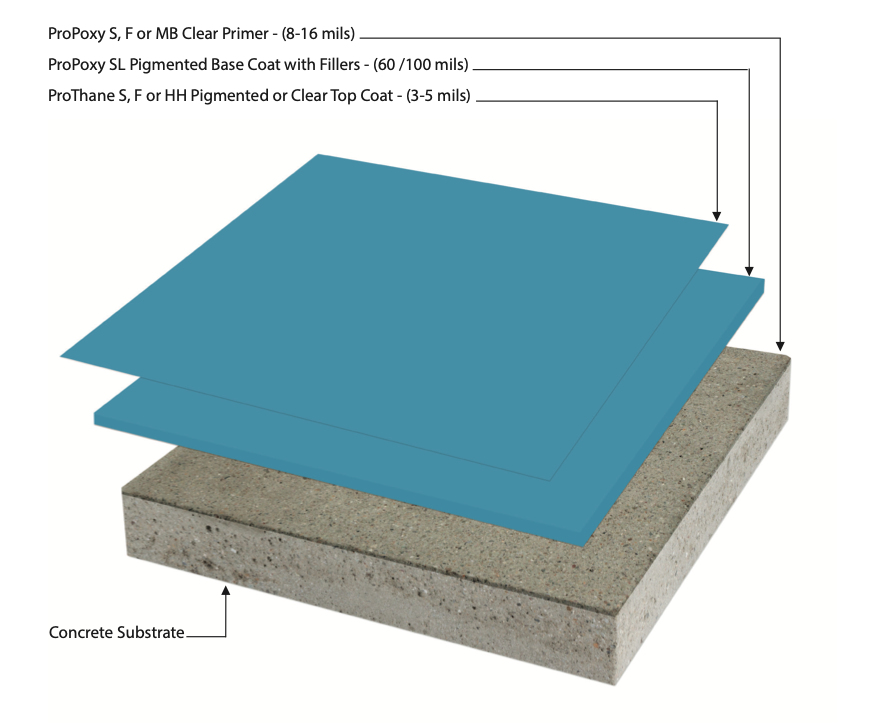

Primer/Sealer

ProPoxy (S/F) or ProPoxy MoistureBLOK (MB)

100% solids epoxy hybrid primers to seal the substrate.

Products Used

Base Coat

ProPoxy SL + 20 lbs ProFill SL Filler

100% solids high-build epoxy combined with 20 lbs of SL filler (2 gal bucket) to produce 60 or 100 mil resurfacing system.

Products Used

Top Coat

ProThane (S/F/HH)

Ultra-high solids urethane topcoat in gloss or satin finish. ProWear can be added for abrasion resistance, and ProGrip for non-slip texture.

Products Used

- 100% Solids Material - Low Odor

- Highly Moisture Tolerant (“MB”)

- Chemical & Stain Resistant

- Good Impact Resistance

- Restores Damaged, Old Concrete

- Excellent Durability & Hard Wearing

- Seamless - Easy to Clean & Maintain

- Universal Colorants - All ProREZ Resins

- UV Stable - Gloss or Satin Finish

- Non-Slip Resistance

- Adhesion Promoter - Tenacious Bonding