ProShield MR-100B and 200B combine 100% solids, pigmented elastomeric hybrids with natural quartz sand aggregate (40 mesh “fine” or 25 mesh “coarse”) broadcasted into the resinous matrix to create a highly durable & resilient seamless floor resurfacing system for industrial, institutional, and commercial settings. The single (100B: 1/8"), double & slurry (200B: 3/16"–1/4") broadcast systems provide excellent impact, chemical & stain resistance. ProShield MR is a workhorse system with added built-in waterproofing & flexibility, meeting or exceeding federal standards for safety and performance.

Contact Sales

View or download detailed information concerning this ProREZ system with the following PDF resources.

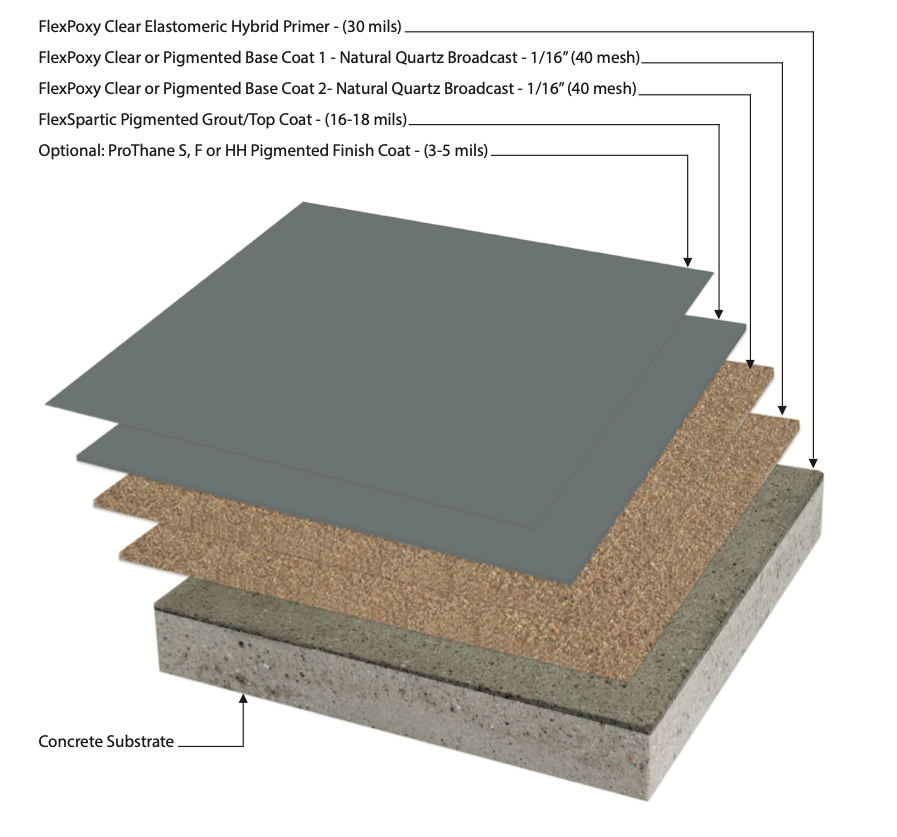

Primer

ProPOXY MB

Moisture-tolerant epoxy primer to enhance adhesion and protect against vapor drive.

Products Used

Basecoat

Elastomeric Epoxy Broadcast with Quartz

Flexible hybrid epoxy broadcast with quartz aggregate for resilient, impact-tolerant surfacing.

Products Used

Topcoat

UV Stable Clear Resin or Satin Finish

Durable clear finish available in gloss or satin. Supports optional non-slip and antimicrobial additives.

Products Used

- Zero VOC - Low Odor

- Highly Moisture Tolerant (“MB” Primer)

- Chemical & Stain Resistant

- Excellent Impact Resistance

- Waterproofing Membrane

- Seamless - Easy to Clean & Maintain

- Optional MicrobeBLOK Additive

- Integral Cove Base

- Universal Colorants - All ProREZ Resins

- UV Stable - Gloss or Satin Finish

- Varied Non-Slip Textures

- Tenacious Bonding with Adhesion Promoter