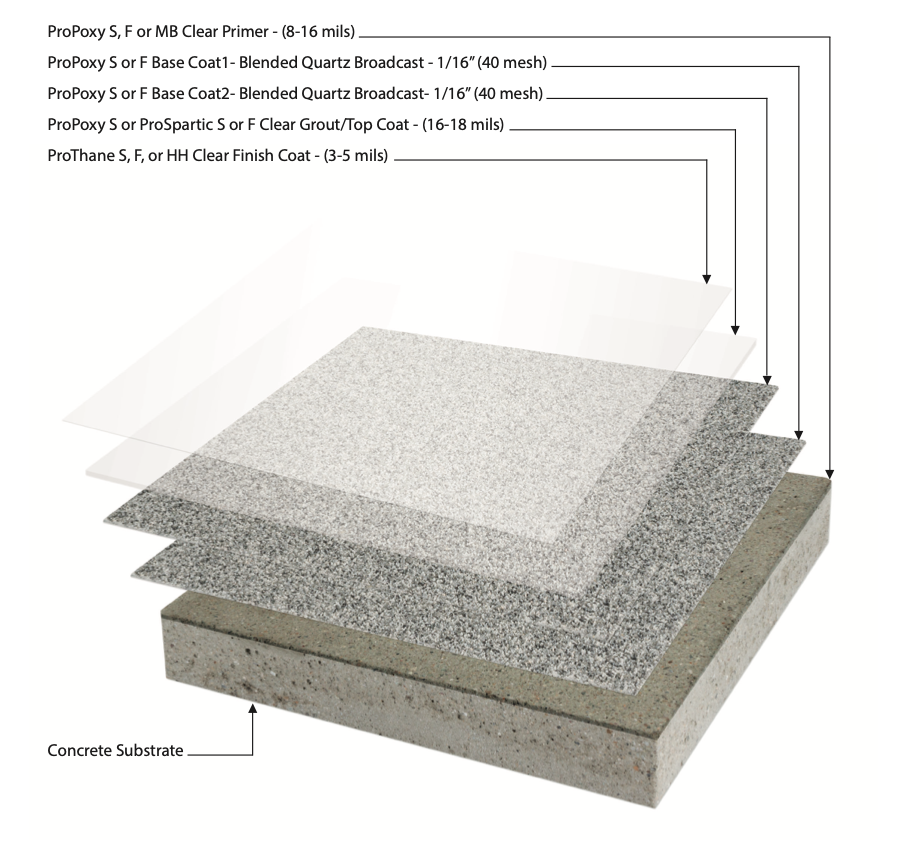

ProQuartz PQ-100 and 200 combine 100% solids, clear epoxy with specially blended colored quartz aggregates (40 mesh “fine” or 25 mesh “coarse”) broadcasted into the resinous matrix to create a highly durable and decorative seamless floor resurfacing system for commercial, industrial, and institutional settings. The single (PQ-100 - 1/16"), double & slurry (PQ-200 - 1/8"–3/16") broadcast systems are hard-wearing and provide excellent chemical, stain, and abrasion resistance. Combine with FlexPoxy, an elastomeric hybrid as a high-build waterproofing membrane system for slab-on-deck applications. The ProQuartz system is available with MicrobeBLOK, an optional antimicrobial additive.

Contact Sales

View or download detailed information concerning this ProREZ system with the following PDF resources.

Primer

ProPOXY MB

Moisture-tolerant, 100% solids epoxy primer that improves substrate bonding and seals vapor emission.

Products Used

Quartz Broadcast Coat

Clear epoxy broadcasted with decorative quartz blend (fine or coarse) for durability and slip resistance.

Products Used

Topcoat

UVR or Satin Resin

High-performance UV stable resin topcoat available in gloss or satin with non-slip texture options.

Products Used

- 100% Solids Material - Low Odor

- Highly Moisture Tolerant (“MB” Primer)

- Chemical & Stain Resistant

- High Build & Decorative

- Good Impact Resistance

- Excellent Durability & Hard-Wearing

- Seamless - Easy to Clean & Maintain

- Optional MicrobeBLOK Additive

- Integral Cove Base

- Colorfast Ceramic Coated Quartz

- Broad Spectrum of Color Quartz Blends

- Custom Blending

- Varied Non-Slip Textures

- UV Stable - Gloss or Satin Finish

- Improved Slip Resistance with ProGrip