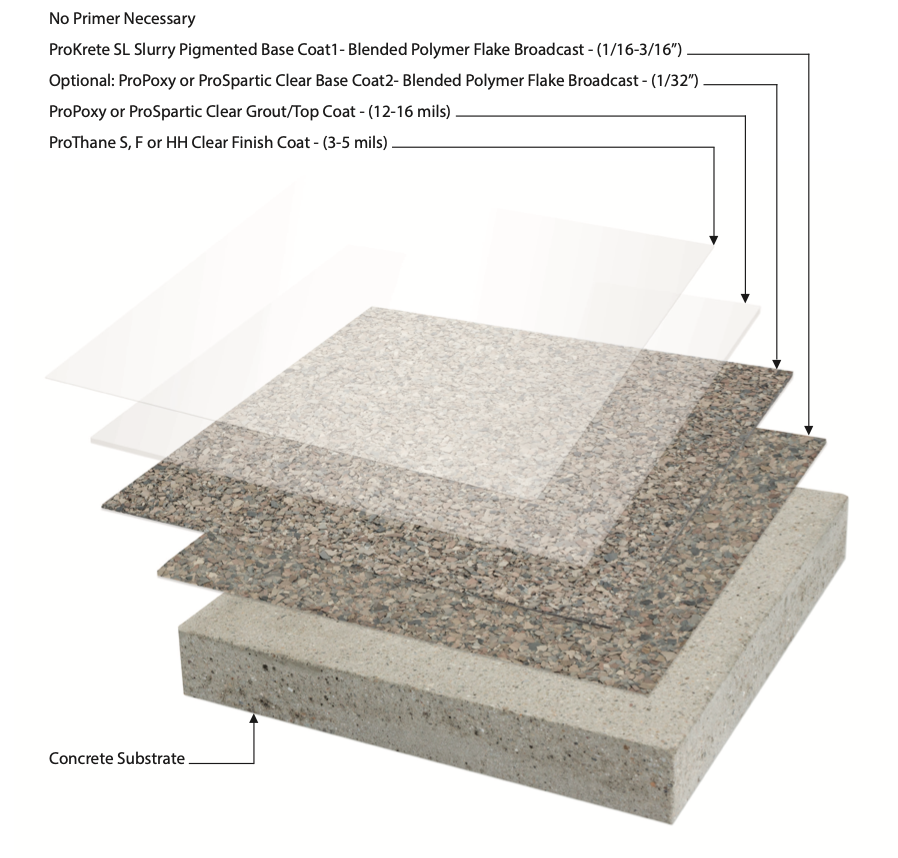

ProKrete SLQ & SLF hybrid systems combine a cementitious urethane slurry base with decorative quartz (SLQ) or flake (SLF) broadcast for resilient, hygienic, and slip-resistant surfaces in demanding environments. These systems are zero VOC, self-priming, and offer tenacious bonding with exceptional resistance to chemicals, stains, and thermal shock. ProSpartic topcoats deliver UV stability, while a range of standard and custom color blends allow tailored aesthetics.

Contact Sales

View or download detailed information concerning this ProREZ system with the following PDF resources.

Basecoat

ProKrete SL Resin + Aggregate

Cementitious urethane basecoat installed at thickness for durability and thermal shock resistance. Broadcast with quartz (SLQ) or flakes (SLF).

Products Used

Topcoat

ProSpartic Resin (Gloss or Satin)

UV stable polyaspartic resin enhances resistance to wear and chemicals. Supports varied textures and optional antimicrobial additives.

Products Used

- Zero VOC Material - Low Odor

- Self-Priming with Tenacious Bond

- UV Resistant with ProSpartic Finish

- Extensive Spectrum of Standard Color Blends

- Optional MicrobeBLOK Additive

- Moisture Tolerant to 20 lbs/1,000 sq ft

- Can Be Applied to New Concrete After 5–7 Days

- Excellent Chemical & Stain Resistance

- Superior Abrasion Resistance

- Field Option for Accelerated Cure

- Improved Slip Resistance with ProGrip