View in-depth reference guides and technical white papers covering specialized flooring concepts. Topics include moisture vapor transmission, squeegee coverage rates, surface prep conditions, and other advanced guidance that supports engineering-level planning.

These guides are ideal for consultants, technical sales teams, and architects seeking to deepen their understanding of resinous flooring science.

Product Reference Guide for ProCOLOR WB

This PDF includes information concerning the ProCOLOR WB Water Based line of colorants.

View PDF

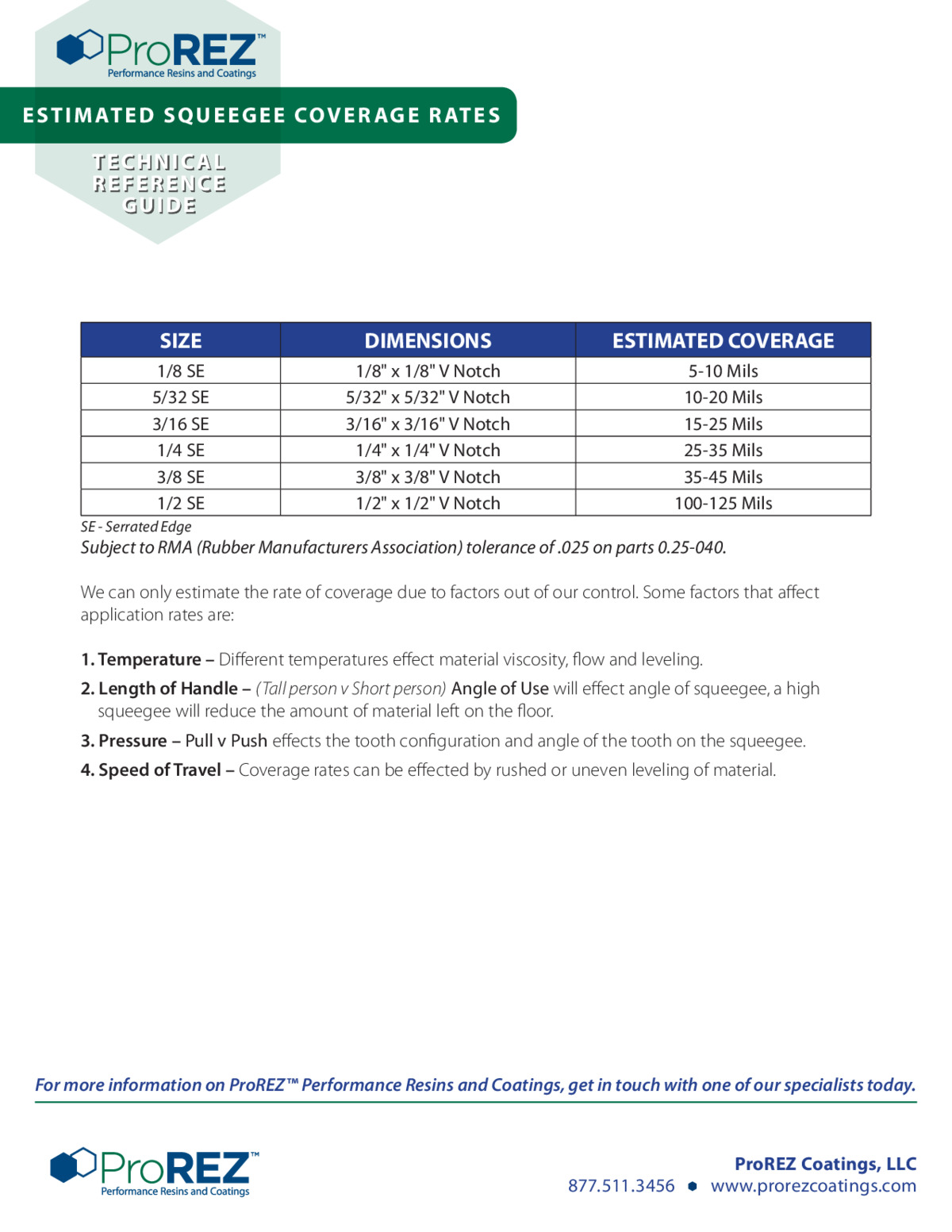

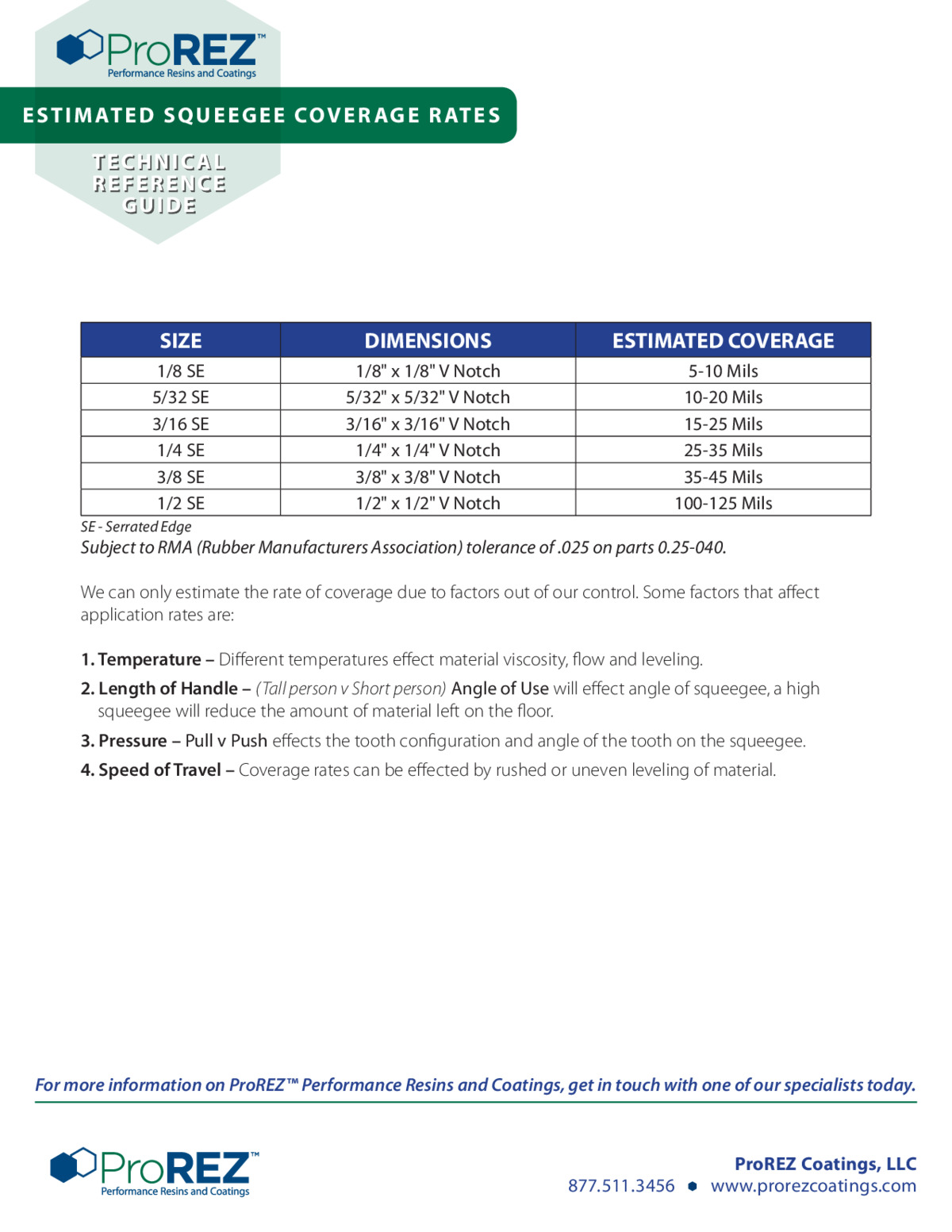

Estimated Squeegee Coverage Rates Technical Reference Guide

This technical reference guide provides a table of serrated edge (SE) trowel sizes—ranging from 1/8″ × 1/8″ up to 1/2″ × 1/2″—with estimated per‑pass coverage in mils (e.g., 5–10 mils, 25–35 mils, etc.). It explains that actual coverage rates can vary due to external factors such as ambient temperature affecting material viscosity, applicator angle and height influencing deposited thickness, and pressure differences between push and pull techniques. The guide notes RMA (Rubber Manufacturers Association) tolerances and warns that uneven leveling or rushed application also alters coverage. It highlights how substrate texture and consistency further influence how much material remains after each pass. Finally, it reminds installers that these estimates are subject to variability and that field tests should be performed for precise coverage rates.

View PDF

Osmotic Moisture‑Induced Blistering Technical Reference Guide

This technical reference guide examines osmotic moisture‑induced blistering in resinous floor systems. It defines the condition, traces its history, and explains how moisture and soluble ions in concrete migrate through semi‑permeable barrier coatings to create blisters. The guide outlines the environmental and substrate factors—such as inadequate vapor barriers, leaks, or residual contaminants—that contribute to osmotic pressure and blister formation. Risk reduction strategies are provided, including ASTM F2170 moisture testing, substrate contamination analysis, and specifying breathable coatings or alternative surface treatments. Finally, it emphasizes thorough communication, proper concrete curing, and inspection practices to prevent costly repairs.

View PDF