Our ProREZ Technical Data Sheets provide detailed information on individual ProREZ products including mix ratios, pot life, cure time, tensile strength, and abrasion resistance. These are crucial for planning, installation, and system compatibility assessments.

Each TDS supports field crews and specifiers by providing the metrics and guidelines needed for proper use and application.

ProCryl Ready Rep TDS

This Technical Data Sheet provides detailed information on ProCRYL Ready Rep, a two-component MMA-based polymer concrete repair system. It includes product description, benefits, packaging details, mix ratios, coverage rates, and curing times. The sheet also outlines technical properties such as compressive and tensile strength, application conditions, and temperature tolerances. Safety considerations, storage requirements, and cleanup instructions are included to ensure proper handling and installation.

View PDF

ProMender Technical Data Sheet

This PDF contains the technical data sheet for ProMender HF, a low-viscosity, pourable polyurethane repair material designed for rapid structural repair of spalled concrete, cracks, and damaged control joints. It highlights the product’s ultra-high solids, zero VOC formulation, rapid cure time (traffic-ready in about 1 hour), and strong bonding properties, making it suitable for warehouses, kitchens, hangars, and industrial floors. The sheet outlines physical properties (1:1 mix ratio, ~4-minute pot life, 75D hardness, 5,500 psi tensile strength), application guidelines, limitations, surface preparation requirements, mixing instructions, and cleanup/disposal directions. Packaging, shelf life, storage conditions, and warranty disclaimers are also included.

View PDF

EcoPoxy Technical Data Sheet

This PDF contains technical specifications for EcoPoxy, a 100% solids, low-odor, two-component cycloaliphatic epoxy coating designed for versatile use as a primer, broadcast coat, body coat, or grout coat. It outlines product features such as excellent adhesion, zero VOCs, self-priming capabilities, universal color pack compatibility, and the option to add an epoxy accelerator. The document provides detailed surface preparation requirements, recommended application tools, mix ratios, coverage rates, and maintenance guidelines. It also includes safety precautions, disposal instructions, and warranty information from ProREZ Coatings.

View PDF

BioTHANE Technical Data Sheet

The PDF describes BioThane, a two-component, plant oil–based polyurethane primer and basecoat system that is high solids, low odor, and zero VOC. It delivers strong adhesion to a wide range of substrates and works effectively as a primer or broadcast coat with quartz or flake media. BioThane cures quickly (2–3 hours recoat time) at a 2:1 resin-to-hardener mix ratio and is versatile across application environments from 40°F to 90°F. Its benefits include rapid recoat cycles, strong chemical resistance, USDA/FDA compliance, and suitability for industries like food processing, healthcare, manufacturing, and garage/service bays.

View PDF

FlexPoxy Technical Data Sheet

This technical data sheet introduces FlexPoxy as a clear, two‑component, low‑odor, 100% solids hybrid epoxy/waterproofing membrane built to bridge substrate movement up to 1/8″ without fracture. It details the product’s elastomeric composition, highlighting features like high elongation and toughness. The document outlines recommended surface preparation steps, mixing ratios, and application methods (spray or trowel). Curing information is provided, including tack‑free and full cure times under different temperature/humidity conditions. Finally, it lists key physical properties such as tensile strength, elongation, abrasion resistance, and elongation retention under cyclic loading.

View PDF

MicrobeBLOK Product Reference Sheet

This product reference sheet explains MicrobeBLOK, an antimicrobial agent designed to inhibit the growth of mold, bacteria, and other microorganisms in resinous flooring systems like epoxies and urethanes. It begins by illustrating how resinous floors can harbor harmful microbes and the potential consequences of surface contamination. The sheet details how MicrobeBLOK can be factory‑treated into selected products or added on site to create a hygienic, longer‑lasting floor finish. It highlights compliance with FDA/USDA standards for use in food‑grade and healthcare environments. Finally, it provides general mixing and handling notes, as well as typical dosage rates to achieve desired antimicrobial protection.

View PDF

ProCryl Cleaner Technical Data Sheet

This technical data sheet defines ProCryl Cleaner as a stabilized, inhibited methyl methacrylate (MMA) monomer solvent formulated for cleaning tools and equipment after installation of ProCryl flooring systems. It outlines key benefits such as compatibility with existing ProCryl floors prior to recoating, use as a smoothing aid in mortar and cove applications, and reusability when stored properly. The document specifies safety and handling instructions, including storage in sealed containers and avoidance of open flames or food contact. Detailed physical properties are provided, including viscosity, flash point, and VOC content. Finally, it lists limitations—e.g., not intended as a thinner for ProCryl resins and maximum reuse cycles before disposal.

View PDF

ProColor Universal Colorants Product Reference Sheet

This product reference sheet introduces ProColor Universal Colorants, the next‑generation pigment system for tinting resinous floor coatings. It begins with a brief description of the Universal Colorants’ color stability advantages over traditional hard‑pack pigments. The document details available packaging (18 standard colors in 1 gal jugs or 5 gal pails), recommended dosage rates (e.g., 8 oz per mixed gallon for full opacity), and estimated coverage rates at different film thicknesses. Typical physical properties are listed, including specific gravity, viscosity, and VOC content, with a note that final coverage depends on system used. The sheet concludes with storage and handling guidelines, emphasizing sealed containers and moderate temperature storage to prevent pigment settling.

View PDF

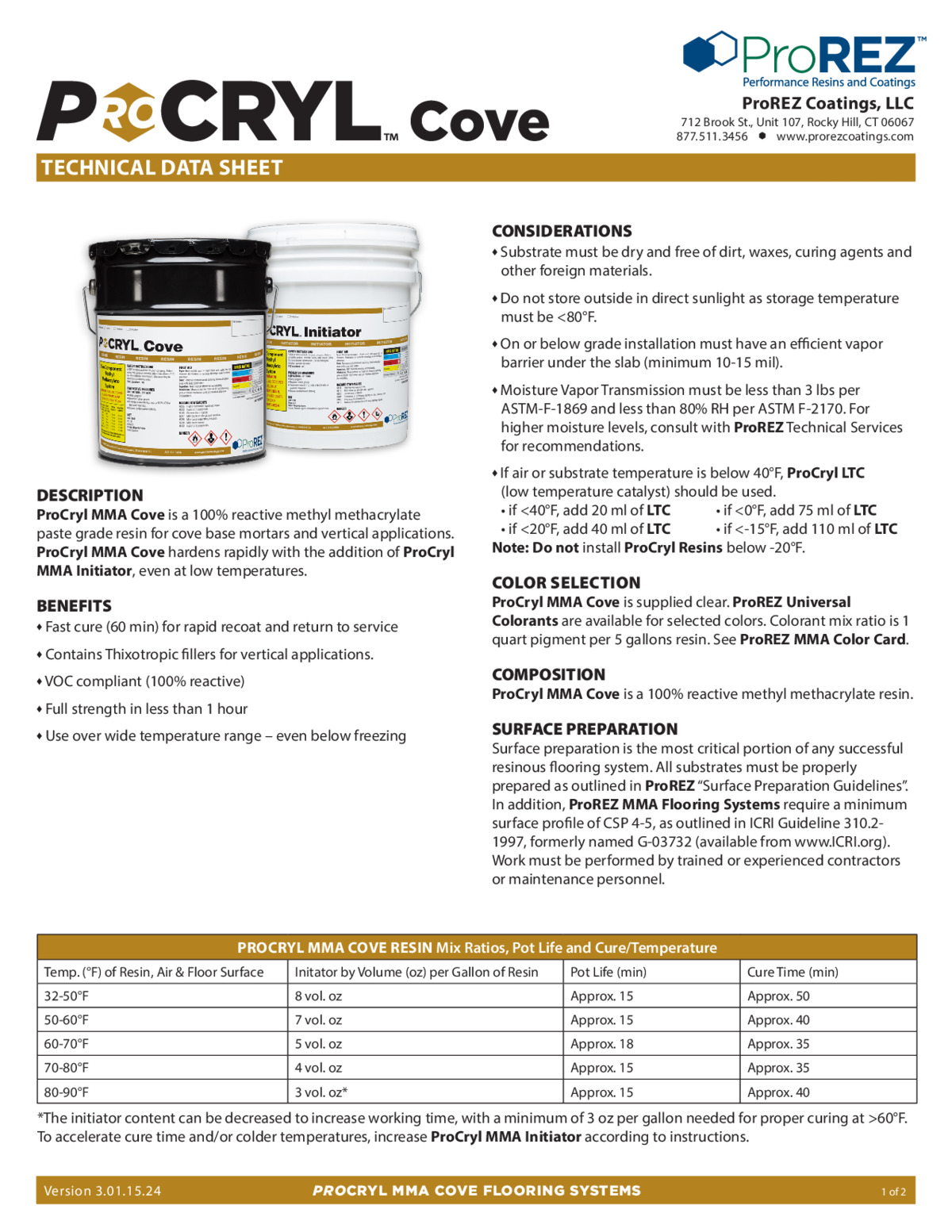

ProCryl MMA Cove Technical Data Sheet

This technical data sheet focuses on ProCryl MMA Cove, a 100% reactive methyl methacrylate (MMA) paste resin designed for vertical cove base mortar and coving installations. It explains the product’s formulation, emphasizing its thixotropic fillers that enable vertical build without sagging, and its low‑temperature cure capability even in freezing conditions. The document provides mixing instructions (exact ratios of resin to initiator), notes on surface preparation (clean, dry, profiled surfaces), and step‑by‑step installation guidelines including trowel application techniques. Cure data is given—typically achieving full strength and ready for service in under one hour. Physical and chemical resistance properties (hardness, chemical exposure limits) complete the sheet, along with storage recommendations and product limitations (e.g., not for horizontal wear surfaces without topcoat).

View PDF

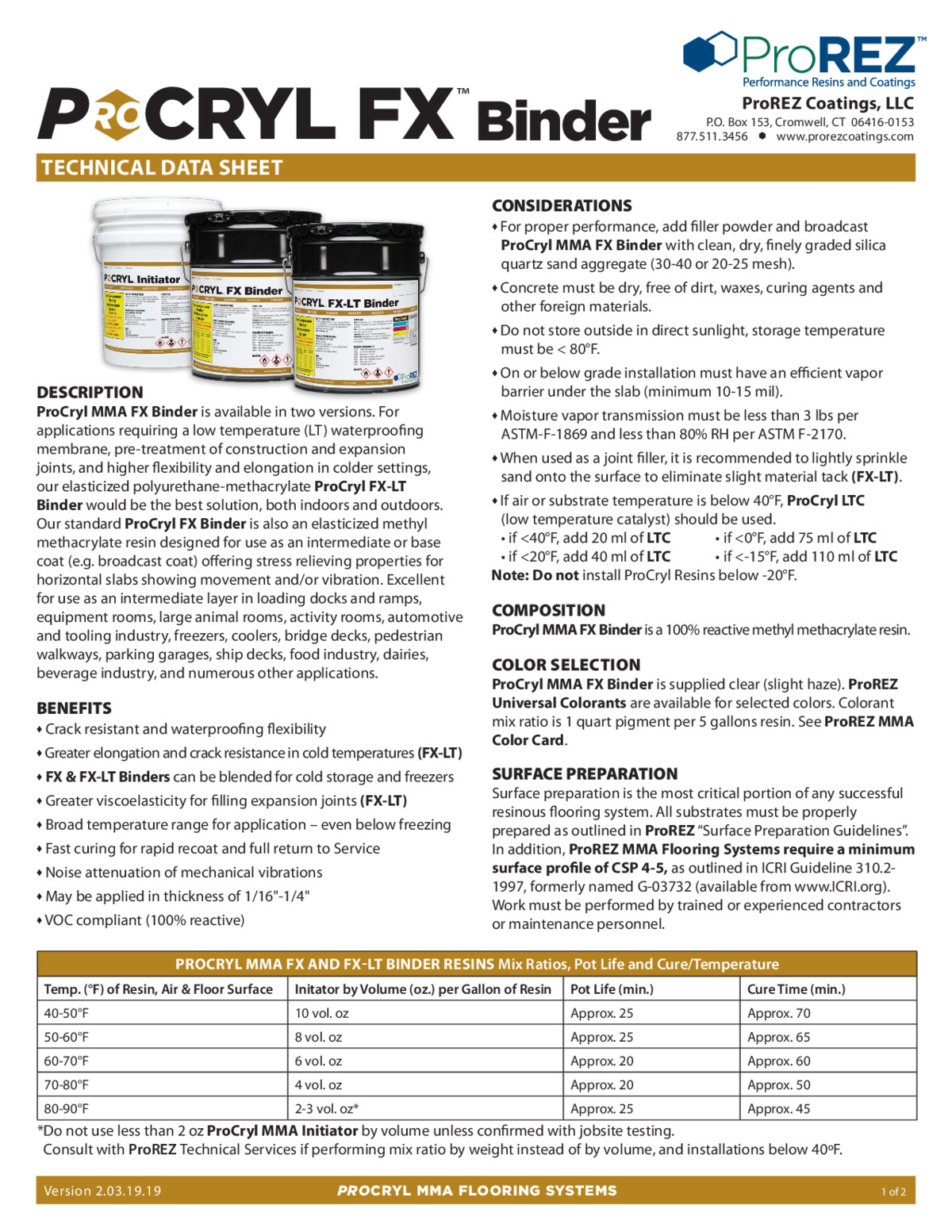

ProCryl FX Binder Technical Data Sheet

This technical data sheet describes ProCryl FX Binder, the binder component used in ProCryl Methyl Methacrylate (MMA) flooring systems. The introduction explains its 100% reactive MMA binder chemistry and how it promotes rapid polymerization even at low ambient temperatures. It outlines recommended surface prep—concrete profiling and moisture checks—and provides precise mixing ratios between the FX Binder and its initiator. Application instructions cover broadcast rates, roller backroll techniques, and environmental controls to minimize fumes. Cure times (light traffic in 30–45 minutes, full service in under 2 hours) and physical properties like tensile strength, flexural modulus, and abrasion resistance are included. Finally, it details chemical exposure limitations and recommended topcoat compatibility.

View PDF

ProCryl HB Binder Technical Data Sheet

This technical data sheet explains ProCryl HB Binder, a high‑build MMA binder used to create thick, trowelable epoxy overlay systems for industrial floors. It starts by outlining the binder’s formulation—including polymer‑grade MMA resins and proprietary thixotropic additives—that enable high‑viscosity, self‑leveling applications. The document details surface preparation requirements such as crack repair, shot blasting, and moisture testing before application. It provides mixing directions (binder to initiator ratio) and installation steps highlighting recommended build thickness per pass, respiration precautions, and temperature constraints. Cure characteristics are listed, indicating full cure within 1 hour and limited shrinkage properties. A table of physical properties (hardness, tensile strength, compressive strength) and chemical spill resistance is included at the end.

View PDF

ProCryl Initiator Technical Data Sheet

This technical data sheet defines ProCryl Initiator, the peroxide catalyst used to start polymerization in ProCryl MMA flooring systems. It begins by describing its BASE peroxide chemistry and recommended storage conditions to maintain activity. The document provides mixing ratios for various MMA resin systems (e.g., binder, primer, cove) and emphasizes precise weight measurements to ensure consistent cure. Detailed handling instructions include personal protective equipment (PPE), ventilated environments, and avoidance of metal contamination. Cure profiles—time to tack‑free, light load, and full cure at different ambient temperatures—are specified. Finally, it outlines disposal guidelines for unused initiator and empty containers with emphasis on local hazardous waste regulations.

View PDF

ProCryl Topcoat Technical Data Sheet

This technical data sheet describes ProCryl Topcoat—a high‑performance, UV‑stable methyl methacrylate (MMA) resin used as a clear or pigmented protective finish on ProCryl MMA floor systems. It begins by highlighting the resin’s 100% reactive, low‑odor formulation and its compatibility with various primers. The document outlines mixing ratios (Topcoat to initiator), best practices for spray or roller application, and recommended film thickness to achieve optimum UV resistance. Cure information is provided, indicating walkable conditions in 30–40 minutes and full chemical cure in under 2 hours. It lists key physical properties—tensile, elongation, abrasion resistance—and details resistance to common chemicals like acids and alkalis. Storage and shelf‑life guidelines (cool, dry, sealed container) complete the sheet.

View PDF

ProCryl Primer Technical Data Sheet

This technical data sheet introduces ProCryl Primer, a methyl methacrylate (MMA) primer formulated to enhance adhesion between concrete substrates and ProCryl MMA floor applications. It describes the product’s 100% reactive MMA chemistry and its ability to penetrate and seal porous concrete. The document provides precise mixing instructions (primer to initiator ratio), recommended substrate temperatures, and moisture limits for concrete prior to application. Application guidelines cover roller or squeegee techniques to achieve 3–5 mils dry film thickness and minimize air entrapment. Cure times (light pedestrian traffic in 20–30 minutes, full overlay in under 1 hour) are stated along with key physical properties (viscosity, tensile, elongation). Finally, it lists substrate compatibility notes and surface preparation requirements (mechanical profiling, moisture testing).

View PDF

ProExtender Topcoat Technical Data Sheet

This technical data sheet covers ProExtender Topcoat—a trowelable extender additive designed to modify viscosity and build properties in ProThane polyurethane topcoat systems. It begins by explaining how ProExtender alters pigment load and rheology for improved workability on vertical surfaces. The document outlines recommended mix ratios when blending ProExtender with ProThane resin to achieve specific build thicknesses (e.g., 10–12 mils per coat). Application instructions cover trowel or squeegee techniques and back‑roll methods to minimize pinholes. Fundamental cure data (tack free in 2–3 hours, full cure in 24 hours) and key physical properties (hardness, elongation, abrasion resistance) are provided. Lastly, it lists storage instructions (store in sealed containers between 50–80 °F) and limitations (not for use in below‑freezing temperatures).

View PDF

ProKrete Technical Data Sheet

This technical data sheet describes ProKrete, a cementitious urethane mortar system designed to deliver rapid cure, high compressive strength, and excellent chemical resistance for heavy‑duty industrial flooring. It begins by detailing the two‑component chemistry—urethane prepolymer and cementitious filler—required for high impact and wear tolerance. The document specifies mixing ratios and the use of power drills with mixing paddles to achieve a uniform, trowelable consistency. Surface prep instructions include shot blasting to achieve a CSP 3–5 profile, with moisture vapor emission rate limits indicated. Application guidelines cover pumping or hand‑trowel methods to achieve 1/4″–3/8″ thickness and quick return to service (≤ 2 hours for light traffic). Physical property tables include compressive strength (> 5,000 psi), tensile strength, and chemical exposure recommendations. Storage and handling notes conclude the sheet, emphasizing dry, cool storage and minimum shelf life of 12 months.

View PDF

ProKrete CM Technical Data Sheet

This technical data sheet covers ProKrete CM, a cementitious urethane topping used for thin‑trowel mortar applications on industrial floors. It begins by outlining the two‑component blend of urethane prepolymer and engineered cementitious fillers that yields a mortar with high compressive strength and rapid set time. Surface preparation instructions specify shot blasting to a CSP 3–5 profile and moisture vapor emission limits ( 6,000 psi, flexural strength, tensile strength) and chemical resistance ratings is included. Finally, storage guidelines (sealed containers, 50–80 °F) and limitations (not for submerged conditions) are listed.

View PDF

ProPoxy Technical Data Sheet

This technical data sheet describes ProPoxy, a two‑component, 100% solids epoxy floor coating formulated for high durability, chemical resistance, and long‑term wear performance. It begins by outlining product composition—including resin/hardener percentages—and VOC content of zero. Surface preparation guidelines require shot blasting or diamond grinding to achieve an ICRI CSP 3–5 profile and moisture intrusion limits (< 4 lbs/1000 ft²/24 hours). Application instructions cover mixing ratios (2:1 by volume), pot life (30 minutes at 70 °F), and recommended film thickness (10–12 mils). Cure data indicates light foot traffic in 8 hours, full cure in 5 days, and temperature constraints during application. A table of physical properties (tensile, flexural, compression, adhesion, impact) and chemical resistance ratings (resistant to acids, caustics, solvents) completes the sheet. Storage recommendations (sealed containers, 50–80 °F) and disposal instructions for leftover material conclude the document.

View PDF

ProPoxy CR Technical Data Sheet

This technical data sheet introduces ProPoxy CR, a cycloaliphatic epoxy floor coating engineered for superior chemical splash and spill resistance in industrial environments. It begins by describing the epoxy’s two‑component formulation, high solids content, and low viscosity to enable good substrate penetration. Surface preparation instructions emphasize shot blasting or concrete diamond grinding to remove contaminants and achieve an ICRI CSP 3–5 profile. Application guidelines cover mixing ratios (3:1 by volume), pot life under various ambient temperatures, and recommended film thickness of 15–20 mils to achieve optimum chemical resistance. Cure data includes tack‑free time (4 hours @ 75 °F), light foot traffic in 16 hours, and full cure in 7 days, with temperature limitations for ambient and substrate. A table of physical and mechanical properties (compressive strength > 8,000 psi, tensile strength, adhesion) and common chemical resistance ratings (salts, acids, solvents) concludes the sheet. Storage and handling guidelines (50–80 °F, sealed containers) are included at the end.

View PDF

ProPoxy MB Technical Data Sheet

This technical data sheet explains ProPoxy MB, a two‑component, metallic epoxy floor system designed to provide a decorative, high‑gloss finish alongside excellent chemical and abrasion resistance. It begins by describing the product’s reflective mica pigments and how they produce a three‑dimensional, metallic appearance when troweled or rolled. Surface preparation instructions require concrete diamond grinding to ICRI CSP 2–3 profile and a clean, dust‑free substrate. Mixing instructions cover blending the pigmented resin with a polyamine hardener at a 2:1 ratio by volume, followed by induction time and slow stirring to avoid entraining air. Application guidelines describe broadcast, backroll, and squeegee techniques to achieve a smooth, blemish‑free metallic effect. Cure data (tack free in 6 hours, full cure in 5 days) and performance properties (compression, abrasion, chemical resistance) are included. Safety and handling instructions (PPE, ventilation) and storage recommendations (sealed pails, 50–80 °F) conclude the sheet.

View PDF

ProPoxy UVR Technical Data Sheet

This technical data sheet introduces ProPoxy UVR, a cycloaliphatic epoxy floor coating formulated for superior UV stability—ideal for environments with intermittent sunlight exposure. It begins by detailing the product’s two‑component, low‑odor formula and high solids content that reduce chalking, yellowing, and gloss loss. Surface preparation guidelines include diamond grinding to an ICRI CSP 3–5 profile and moisture vapor emission testing to ensure substrate readiness. Application instructions cover mixing ratios (3:1 by volume), pot life at various temperatures, and recommended film thicknesses (10–15 mils) for optimal UV protection. Cure data includes light foot traffic in 8 hours and full chemical cure in 5 days, with temperature limitations. A performance table lists tensile strength, flexural modulus, gloss retention after UV exposure, and chemical resistance. Storage and handling notes (sealed containers, 60–80 °F) close the document.

View PDF

ProPoxy WB Technical Data Sheet

This technical data sheet describes ProPoxy WB, a single‑component, water‑based epoxy floor coating designed to offer durable performance with lower VOC content. It begins by detailing the product’s waterborne formulation, which simplifies cleanup and reduces odor compared to 100% solids epoxies. Surface preparation guidelines include shot blasting or diamond grinding to achieve a clean, profiled substrate, with moisture limits (< 5 lbs/1000 ft²/24 hours). Application instructions cover brush, roll, or spray techniques, recommended coverage rates (300–400 ft²/gal at 2 mils), and ambient temperature constraints. Cure data includes recoat window (4–6 hours) and full cure in 48 hours, with notes on cold or humid conditions. A table of performance properties (meets ASTM standards for abrasion resistance, tensile strength) and chemical resistance ratings (detergents, mild acids) is provided. Storage and handling guidelines (store in sealed pails, 40–90 °F) round out the sheet.

View PDF

ProSeal Technical Data Sheet

This technical data sheet describes ProSeal, a two‑component sealer additive engineered to boost the abrasion resistance and chemical resistance of protective polyurethane and epoxy floor systems. It begins by explaining ProSeal’s resin‑based formulation and its compatibility with existing ProThane, ProPoxy, and ProCryl coatings. The document outlines surface preparation requirements (clean, dry, profiled concrete or existing coatings) and mixing instructions to blend ProSeal with a specified polymer base. Application guidelines cover roller or squeegee techniques, target film thickness (1–2 mils), and recommended ambient conditions (50–85 °F, < 80% RH). Cure information indicates tack‑free in 2 hours, full cure in 24 hours, and recoat windows up to 72 hours. Finally, a table lists key physical properties (hardness, tensile, abrasion resistance), chemical spot test results, and UV stability data. Storage notes (sealed containers, 50–80 °F) complete the sheet.

View PDF

ProSpartic Technical Data Sheet

This technical data sheet introduces ProSpartic, a methyl methacrylate (MMA) floor coating system designed for rapid cure and high wear resistance in industrial settings. It begins by describing the two-component MMA resin formulation and its low odor, fast‑setting characteristics—typically achieving safe foot traffic in 30 minutes and full service in 2 hours. Surface preparation guidelines call for shot blasting or diamond grinding to an ICRI CSP 3–5 profile and ensuring substrate moisture below 4%. Detailed mixing instructions specify the ratio of ProSpartic resin to initiator, followed by troweling or squeegee application methods. Cure and performance data include Durometer hardness, tensile strength, flexural modulus, and abrasion resistance (Taber abrasion values), as well as chemical resistance to common industrial chemicals. Storage and handling notes (store in sealed containers between 60–80 °F) conclude the sheet.

View PDF

ProThane Technical Data Sheet

This technical data sheet describes ProThane—a two‑component, hybrid polyurethane topcoat formulated for abrasion resistance, UV stability, and long‑term durability on industrial floors. It begins by outlining ProThane’s chemical composition, including resin, hardener, and self‑crosslinking additives that yield a low‑odor, 100% solids finish. Surface preparation instructions focus on diamond grinding to achieve a CSP 3–5 profile, moisture limits (< 3 lbs/1000 ft²/24 hrs), and the use of appropriate primers for porous substrates. The document details mixing ratios (ProThane resin to hardener), pot life (15 minutes at 75 °F), and spray/roller application methods to achieve 2–3 coats at 5–8 mils each. Cure data includes tack free in 4 hours, light foot traffic in 6 hours, and full cure in 24 hours, with performance properties such as Shore A hardness, tensile strength, elongation, and chemical resistance. Finally, it provides storage guidelines (sealed pails, 60–80 °F) and disposal notes for leftover material.

View PDF

ProThane WB Technical Data Sheet

This technical data sheet describes ProThane WB—a single‑component, UV‑stable waterborne polyurethane topcoat designed to offer abrasion resistance and a range of finishes (semi‑gloss, satin, matte) with low VOC content. It explains the resin’s advanced self‑crosslinking mechanism that yields performance on par with two‑component moisture‑cured urethanes. Surface preparation instructions include diamond grinding for profile, moisture testing, and application temperature ranges (50–90 °F). Application guidelines cover brush, roller, or spray methods, with recommended mil thickness (2–3 mils per coat) and recoat windows. Cure times (tack free in 2 hours, full cure in 24 hours) and performance properties (hardness, ASTM abrasion, adhesion, UV stability) are provided. Chemical resistance data and cleaning instructions finish the sheet, followed by storage notes (sealed pails, 60–80 °F) and disposal requirements.

View PDF