View detailed overviews of complete ProREZ systems, including performance characteristics, system build-ups, and use-case recommendations. These sheets provide quick reference for selecting the right system based on environment, durability, and aesthetics.

Each document covers intended industries, layer types, application thicknesses, and optional configurations.

ProCryl CQ System Data Sheet

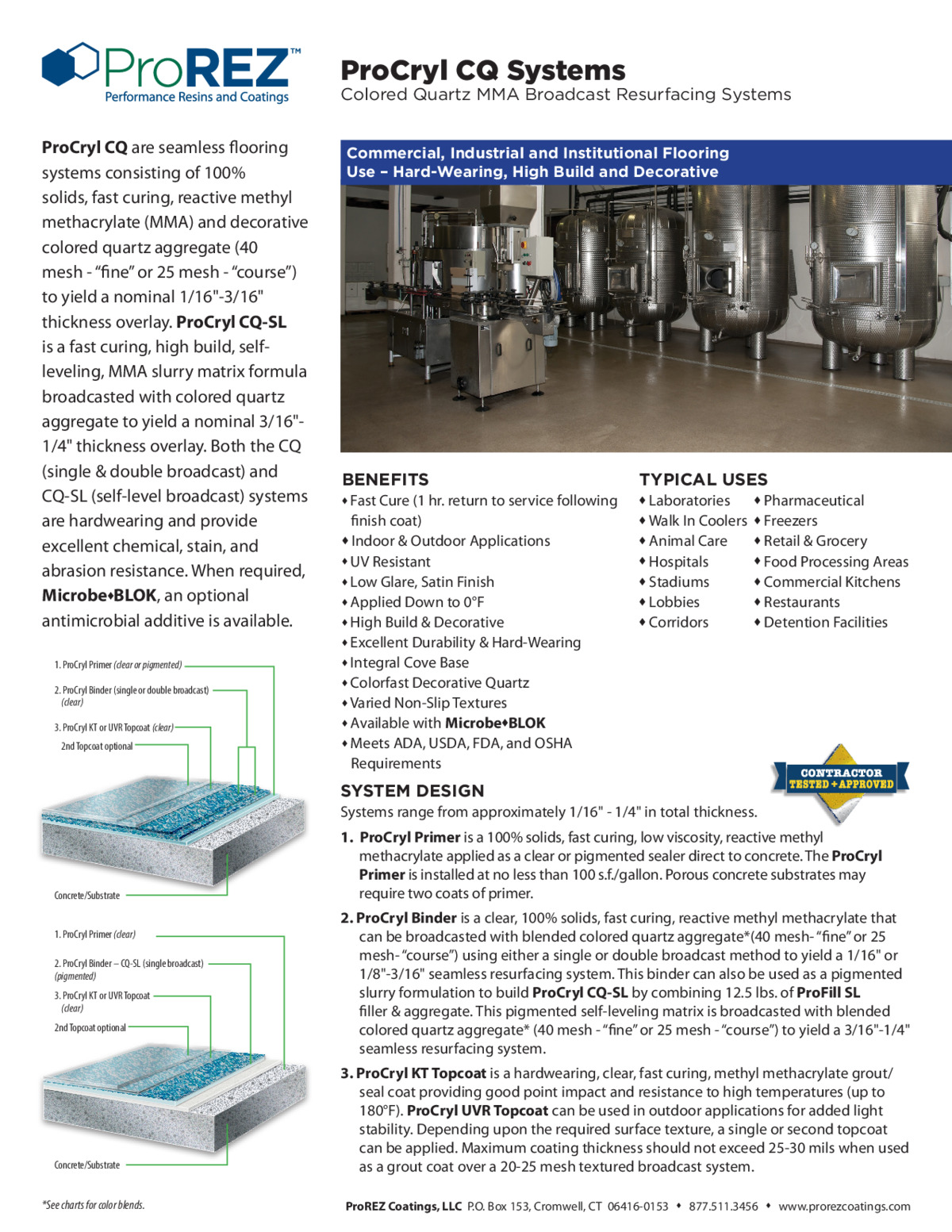

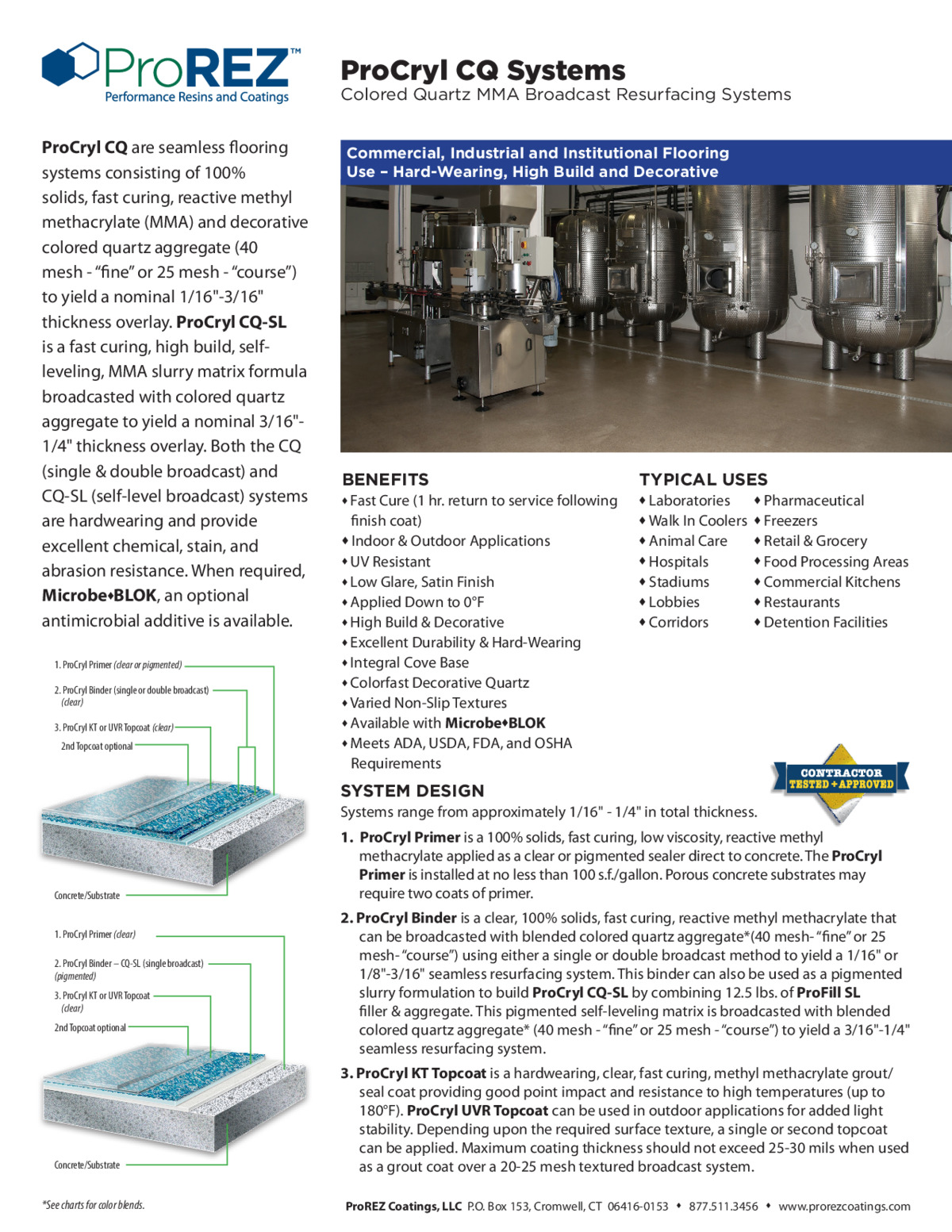

This system data sheet covers ProCryl CQ, a seamless flooring system that combines 100% solids methyl methacrylate (MMA) binder with color quartz chips for a high‑durability, decorative finish. It begins by listing benefits—rapid cure (1 hour to service), UV resistance, low‑temperature application (down to 0 °F), and integral cove base options. The document outlines the standard build‑up: ProCryl primer, binder with single or double quartz broadcast, and a UV‑stable topcoat (with optional second coat). Surface preparation notes include concrete profiling, moisture limits, and primer selection. Finally, it provides general performance characteristics such as abrasion resistance, chemical resistance, and typical color blends.

View PDF

ProCryl SC System Data Sheet

This system data sheet describes ProCryl SC, a seamless, self‑colored quartz flooring system built on 100% solids MMA binder. It highlights benefits like rapid cure (1 hour return to service), UV stability, satin finish, and low‑temperature application down to 0 °F. The guide outlines the component sequence—ProCryl primer, binder coat with broadcast of pigmented quartz, and a clear UV‑resistant topcoat. Surface preparation recommendations include concrete profiling, moisture testing, and primer selection for maximum adhesion. Finally, it provides key performance data such as hardness, abrasion resistance, and typical film thickness for decorative slip resistance.

View PDF

ProCryl SF System Data Sheet

This system data sheet covers ProCryl SF (Shop Floor), an MMA quartz broadcast system designed for durable, seamless resurfacing in industrial and commercial settings. It begins by listing benefits—rapid cure (1 hour return to service), UV stability, stain and chemical resistance, and a satin, slip-resistant finish. The document outlines the standard build‑up: ProCryl primer, MMA binder coat broadcast with natural quartz sand (25 or 40 mesh), and a pigmented topcoat such as ProCryl KT or UVR (plus optional second topcoat). Surface preparation instructions include concrete profiling to CSP 3–5 and evaluation of substrate porosity to determine if additional primer is needed. Finally, it provides build details for single (1/16") and double (1/8"–3/16") broadcast systems, with optional flexible binder for mechanical rooms, decks, and high-movement areas.

View PDF

ProShield SL System Data Sheet

This system data sheet describes ProShield SL-60 and SL-100, high-build, 100% solids epoxy flooring systems designed for seamless, durable protection in industrial and commercial environments. It begins by outlining benefits such as low odor, moisture tolerance, chemical and stain resistance, excellent durability, and UV stability with gloss or satin finish options. The system consists of a ProPoxy primer, ProPoxy SL resin combined with SL filler to achieve 60–100 mil thickness, and a ProThane topcoat. Optional additives include ProGrip for slip resistance and ProWear for enhanced abrasion resistance. Surface preparation guidelines include shot blasting or diamond grinding to achieve a CSP 3–5 profile and the use of moisture-tolerant primers where needed. The sheet also lists typical uses such as manufacturing, clean rooms, hangars, loading docks, corridors, and laboratories.

View PDF

ProLumina System Data Sheet

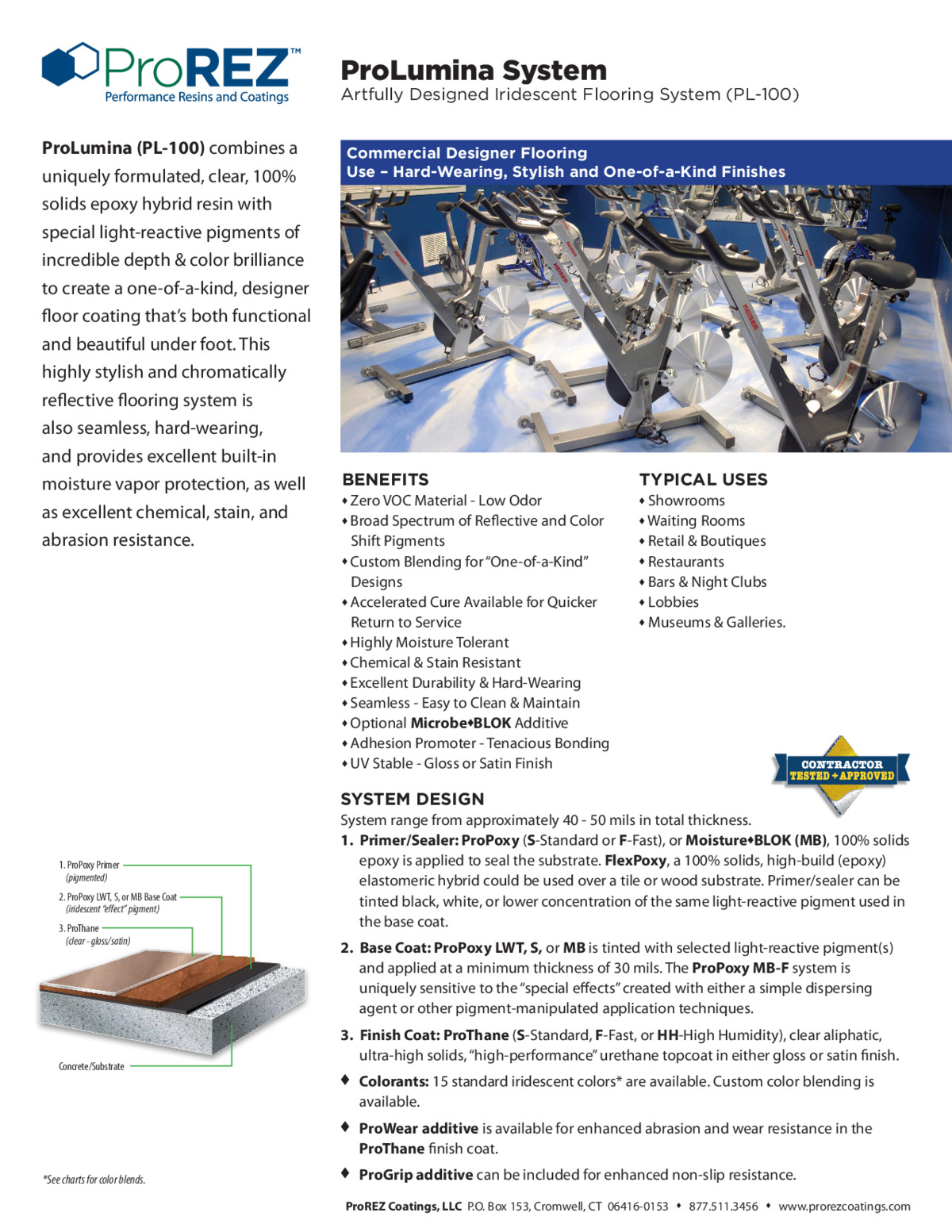

This system data sheet introduces ProLumina (PL‑100), a 100% solids, light-reactive epoxy hybrid floor system designed for high-definition, iridescent finishes. It begins by detailing the color-shifting pigments that produce multi-dimensional effects under changing light conditions. The document outlines substrate preparation—shot blasting or diamond grinding to a CSP 3–5 profile, with optional black or pigmented primer for enhanced visual depth. Mixing instructions include combining ProPoxy resin with the selected effect pigments, followed by base coat application and a clear ProThane urethane topcoat in gloss or satin. The system offers built-in moisture vapor protection, chemical and abrasion resistance, and compatibility with additives like MicrobeuBLOK, ProWear, and ProGrip for added performance and customization.

View PDF

ProCryl SL/SLB System Data Sheet

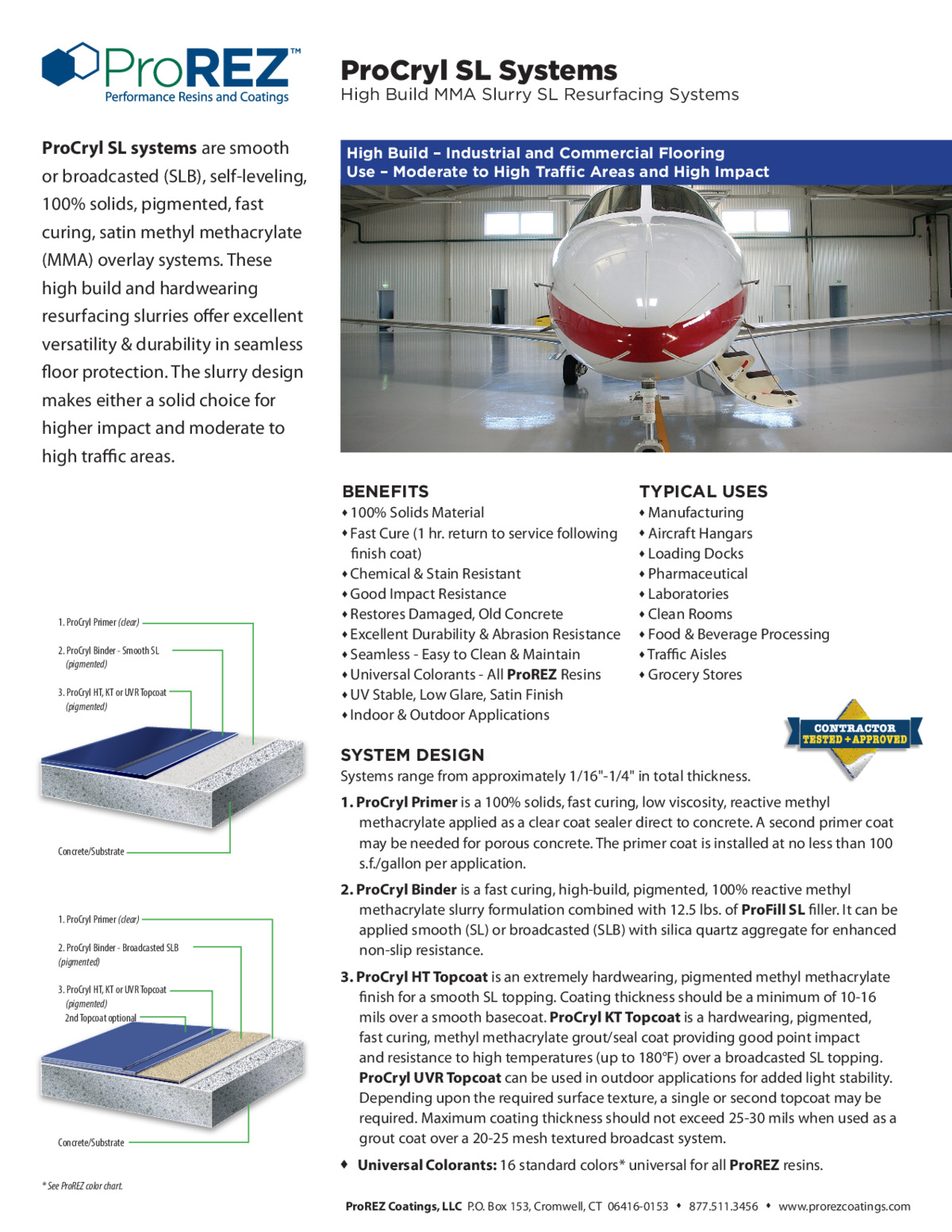

This system data sheet covers ProCryl SL and SLB, self-leveling MMA slurry systems that deliver seamless, high-performance flooring for industrial and commercial use. It begins by listing benefits such as fast cure (1 hour return to service after topcoat), UV stability, and excellent resistance to impact, chemicals, and stains. The document outlines surface preparation—shot blasting or grinding to a CSP 3–5 profile with proper moisture evaluation—followed by mixing instructions for the MMA binder and filler blend. Application is done by trowel as a smooth topping (SL) or as a broadcast system (SLB) using natural quartz for added texture and slip resistance. Pigmented ProCryl topcoats (HT, KT, or UVR) are then applied based on the surface profile and exposure. Finally, it includes optional second topcoats, additive compatibility, and performance data.

View PDF

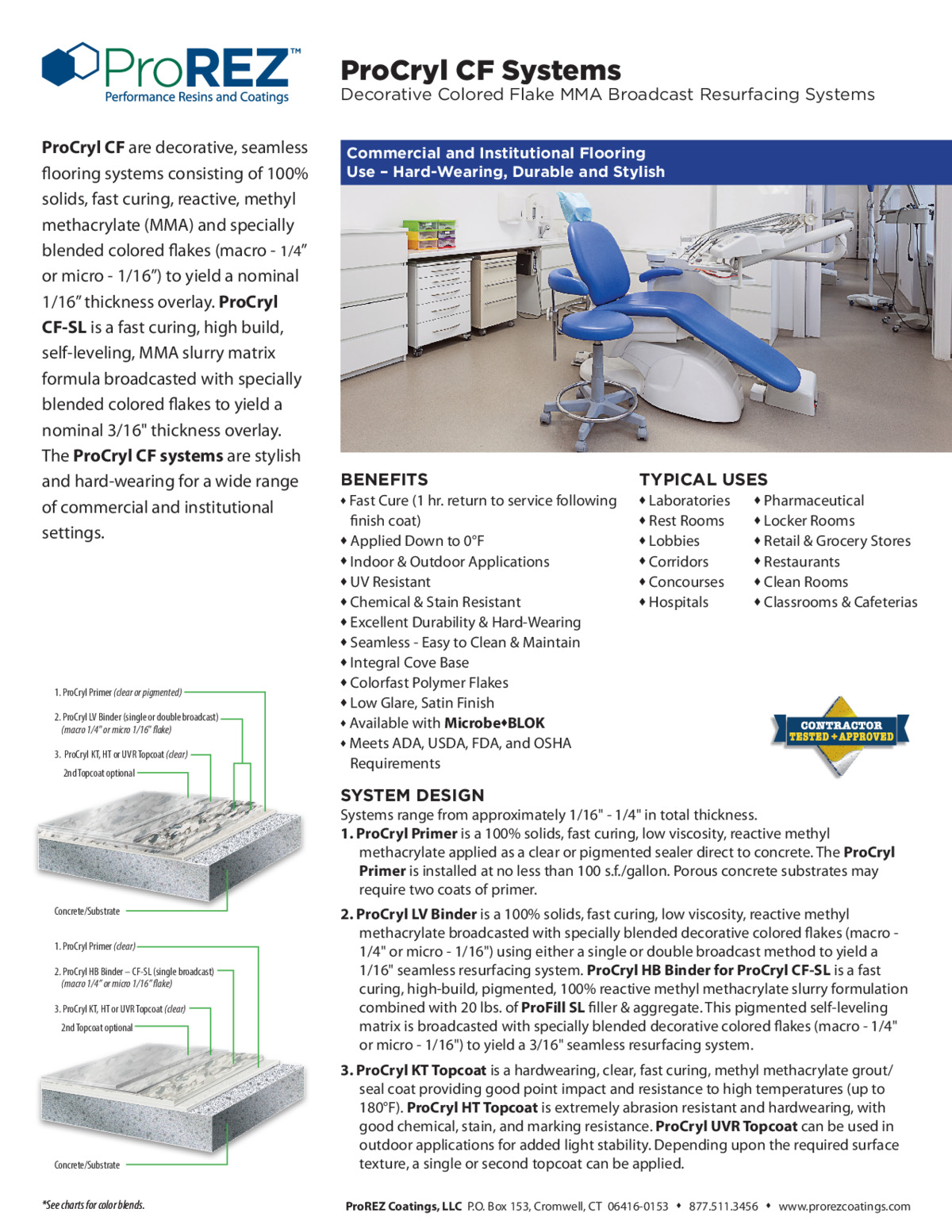

ProCryl CF System Data Sheet

This system data sheet describes ProCryl CF, a seamless MMA flooring system that incorporates colored vinyl flake broadcast for a decorative, slip‑resistant finish. It begins by listing benefits—rapid cure (30 minutes to light traffic), UV stability, and low‑odor for indoor/outdoor use. The document outlines substrate preparation—diamond grinding to ICRI CSP 3–5, moisture vapor emission limits, and the use of a ProCryl primer. It details mixing ratios and broadcast rates for vinyl flake, followed by a clear MMA topcoat to seal the flake. Finally, it provides key physical properties—tensile strength, abrasion resistance, and flexibility—plus cure times and recommended film thickness.

View PDF

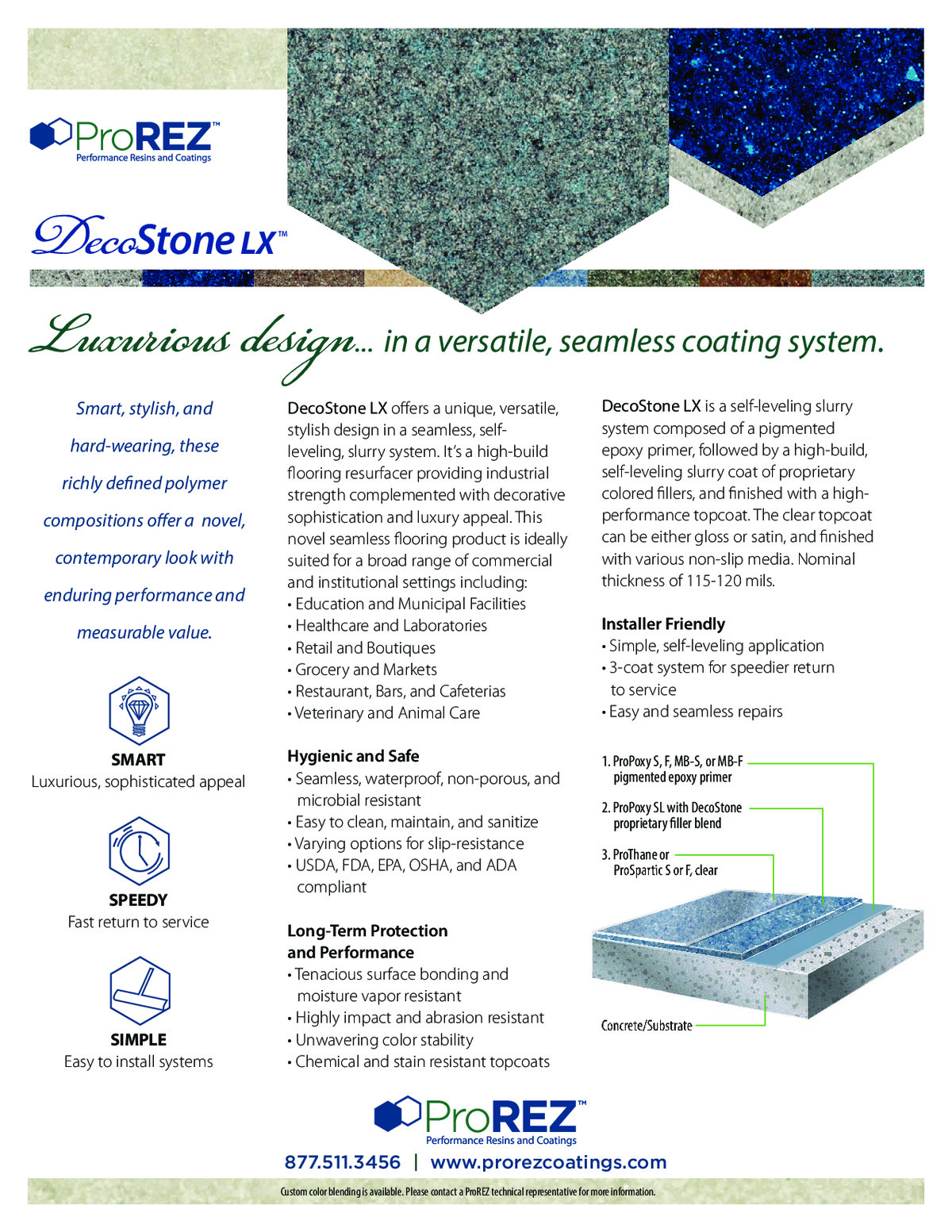

DecoStone System Data Sheet

This system data sheet presents the DecoStone LX Series color guide, which showcases blended color samples for decorative quartz self‑leveling systems. It lists standard color names—Moondust, Galaxy, Light Blue, Deep Blue, Nutmeg, Cinnamon, and more—with sample swatches. The document emphasizes that the printed colors are approximations and recommends contacting a ProREZ technical representative for exact slurry values when specifying a specific shade. It advises testing field samples before final selection to ensure color accuracy under actual lighting conditions. Finally, it provides a brief overview of the DecoStone system’s use in creating seamless, self‑leveling decorative floors.

View PDF

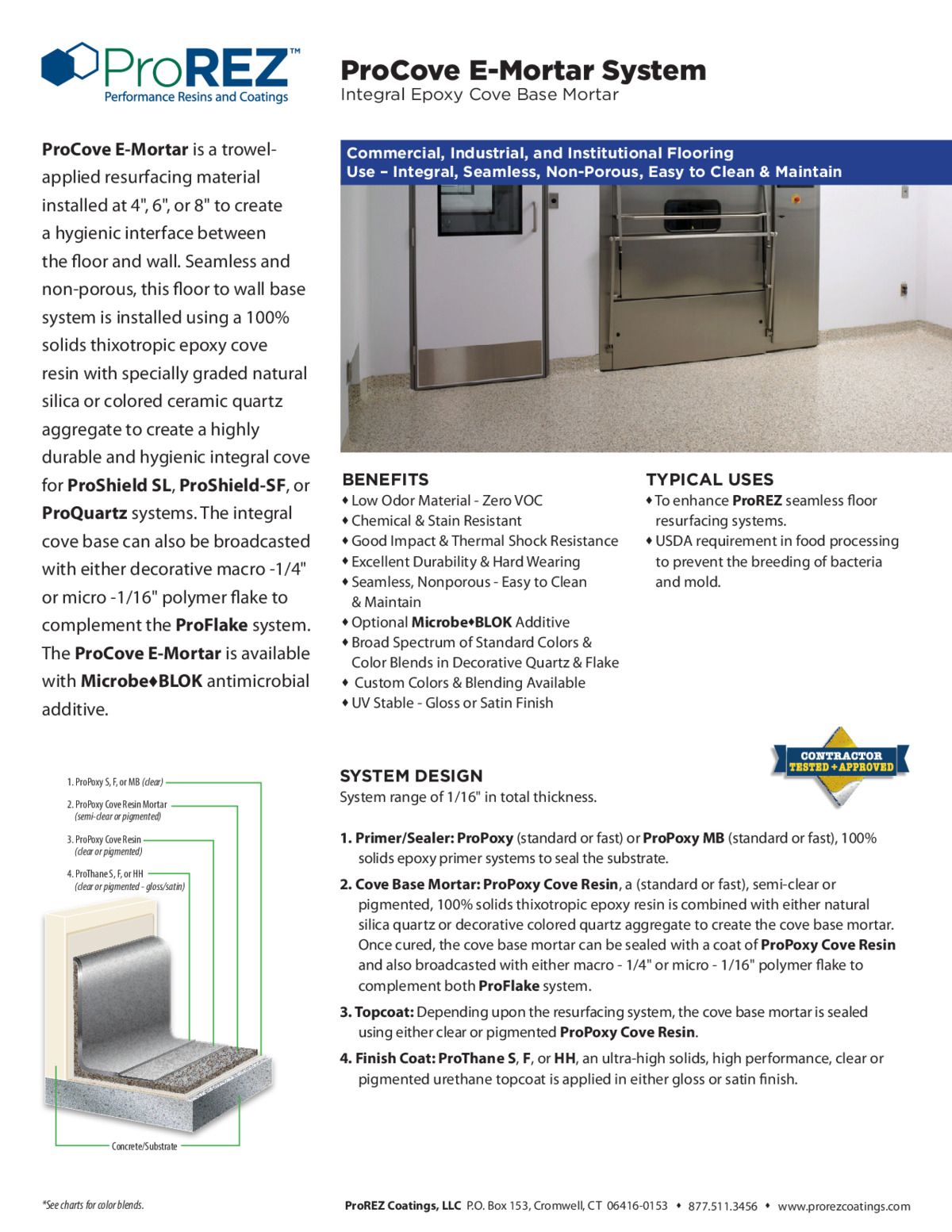

ProCove E Mortar System Data Sheet

This system data sheet describes ProCove E-Mortar, a trowel-applied epoxy cove base system designed to form seamless, durable transitions between floors and walls. It begins by outlining the product’s composition—100% solids, thixotropic epoxy resin combined with silica or colored quartz aggregates—to create a dense, nonporous mortar for hygienic environments. The document includes surface preparation guidelines such as shot blasting to a CSP 3–5 profile and priming with ProPoxy or MB for moisture control. Mixing instructions cover combining the resin with aggregate to achieve a smooth or decorative finish, with hand-trowel application at 4″, 6″, or 8″ height. The cured mortar is sealed with ProPoxy Cove Resin and may receive a ProThane finish coat in gloss or satin. Optional MicrobeuBLOK additive and polymer flake broadcast are also supported.

View PDF

ProCove UC Mortar System Data Sheet

This system data sheet describes ProCove UC-Mortar, a trowel-applied cementitious urethane system designed to create integral cove bases at 4", 6", or 8" heights for seamless floor-to-wall transitions. It begins by detailing the low-odor, zero-VOC matrix composed of urethane polymer and natural silica or decorative flake aggregates. The document outlines substrate preparation—diamond grinding or shot blasting to an ICRI CSP 3–5 profile—and recommends moisture-tolerant primers when needed. ProCove is mixed using pre-measured kits to ensure proper ratios, then hand-applied to form a smooth or textured cove. Depending on the flooring system, topcoats include ProPoxy Cove Resin, ProKrete TF, or ProSpartic polyaspartic, with optional polymer flake broadcast for decorative applications. The system also supports antimicrobial additive integration for hygienic environments.

View PDF

ProFlake Systems Data Sheet

This system data sheet covers ProFlake, a decorative flooring system that uses vinyl flake broadcast over an epoxy base to create a seamless, customizable finish. It begins by listing benefits such as high durability, decorative aesthetics, and chemical resistance. The document outlines substrate preparation—diamond grinding or shot blasting to achieve an ICRI CSP 3–5 profile and performing moisture tests—followed by mixing instructions for the epoxy binder. It details broadcast rates for vinyl flake (e.g., 1–1.5 lb/ft²) and backrolling techniques to achieve an even distribution and a dense, slip‑resistant surface. Performance properties such as abrasion resistance, tensile strength, and chemical resistance are provided, along with topcoat recommendations and cure times (tack free in 6 hours, full cure in 48 hours).

View PDF

ProKrete SLQ/SLF Systems Data Sheet

This system data sheet describes ProKrete SLQ and SLF, cementitious urethane screed systems designed for self‑leveling (SLQ) and semi‑lightweight flowable (SLF) applications. It begins by detailing the two‑component chemistry—urethane prepolymer combined with engineered cementitious fillers—to produce a mortar that flows smoothly and cures quickly. Substrate preparation requirements include shot blasting to ICRI CSP 3–5, moisture vapor testing, and crack repair. Mixing ratios, pot life (3–5 minutes), and pump or hand placement instructions are provided to achieve thicknesses from 1/8″ to 3/4″. Cure data indicates light traffic in 2 hours and full cure in 24 hours. Physical properties such as compressive strength > 5,500 psi, flexural strength, and chemical resistance are listed, along with recommended sealers or coatings for final finish.

View PDF

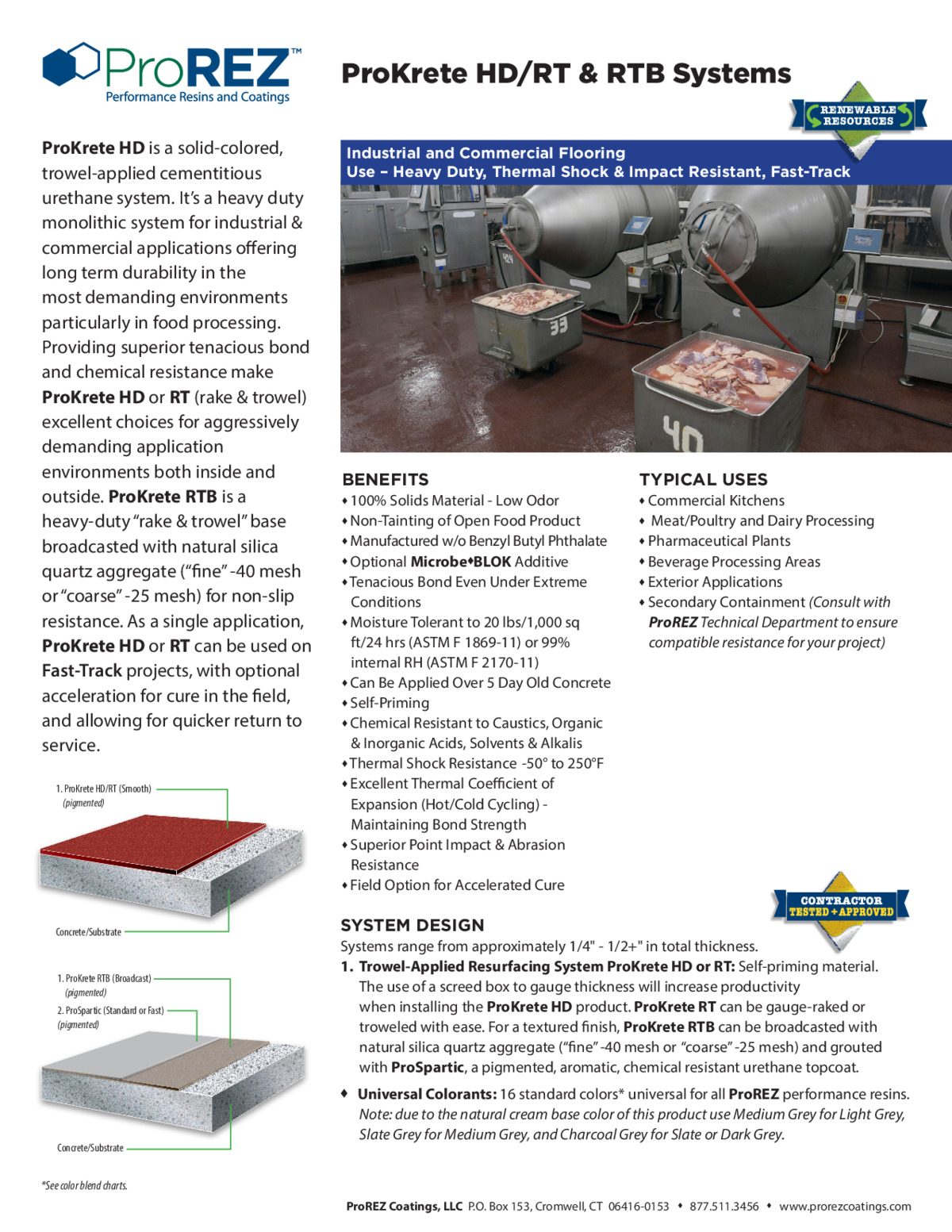

ProKrete HD-RT RTB System Data Sheet

This system data sheet covers ProKrete HDRT RTB, a high‑density, rapid‑turnaround cementitious urethane system engineered for quick‑return‑to‑service floors. It begins by describing the product’s advanced blend of urethane prepolymer and high‑density fillers that deliver compressive strength > 6,000 psi with minimal shrinkage. Substrate preparation includes shot blasting to ICRI CSP 3–5, moisture limits (< 3 lbs/1000 ft²/24 hrs), and concrete repair. Mixing instructions emphasize rapid mixing and placement within a 3–4 minute pot life. Installation guidelines cover power troweling or hand‑troweling to achieve 1/8″–1/4″ thickness, with light traffic in 2 hours and full cure in 6 hours. Physical and mechanical properties such as flexural strength, abrasion resistance, and chemical resistance are provided, along with recommended sealers for final finish.

View PDF

ProKrete SL-SLB System Data Sheet

This system data sheet describes ProKrete SL and SLB, cementitious urethane slurry systems engineered for high-performance industrial and commercial flooring. It begins by detailing the composition—a durable, pigmented urethane slurry applied smooth (SL) or with a silica quartz broadcast (SLB) for added slip resistance. Surface preparation includes shot blasting or grinding to an ICRI CSP 3–5 profile and optional priming to prevent pinholes or outgassing. Mixing instructions outline pre-measured kits applied by trowel or squeegee, with optional accelerators for faster turnaround. SLB systems are topped with ProSpartic, ProKrete TF, or ProCryl MMA topcoats depending on gloss level, cure time, and chemical resistance needs. Finally, the sheet lists thermal shock resistance (up to 250°F), moisture tolerance, chemical durability, and suitable use in food, pharma, automotive, and exterior applications.

View PDF

ProQuartz Systems Data Sheet

This system data sheet introduces ProQuartz, a decorative epoxy flooring system that uses broadcast quartz chips for a seamless, slip‑resistant surface. It begins by explaining the system benefits—customizable color blends, excellent abrasion resistance, and chemical resistance. Substrate preparation guidelines include diamond grinding to achieve an ICRI CSP 3–5 profile and ensuring moisture levels are below recommended limits. The document details mixing the epoxy binder, broadcasting colored quartz at specified rates, and backrolling to embed the chips, followed by a clear epoxy topcoat for protection and gloss. Key performance properties such as tensile strength, abrasion resistance, and slip resistance (ASTM D2047) are provided, along with cure times (tack free in 6 hours, full cure in 48 hours).

View PDF

ProSeal CS System Data Sheet

This system data sheet covers ProSeal CS, a two‑component sealer additive engineered to enhance abrasion and chemical resistance in protective epoxy or polyurethane floor systems. It begins by describing ProSeal CS chemistry—high‑performance resin blended with specialty additives—and its compatibility with ProThane, ProPoxy, and ProCryl coatings. Surface preparation requirements include a clean, profiled substrate (ICRI CSP 3–5) and moisture vapor emission testing. The document provides mixing instructions for blending ProSeal CS with a specified polymer base, followed by roller or squeegee application to achieve 1–2 mils dry film thickness. Cure data includes tack free in 2 hours and full cure in 24 hours. A table of physical properties (hardness, tensile strength, abrasion resistance) and chemical spot test results is provided, along with storage and handling guidelines (store in sealed containers, 50–80 °F).

View PDF

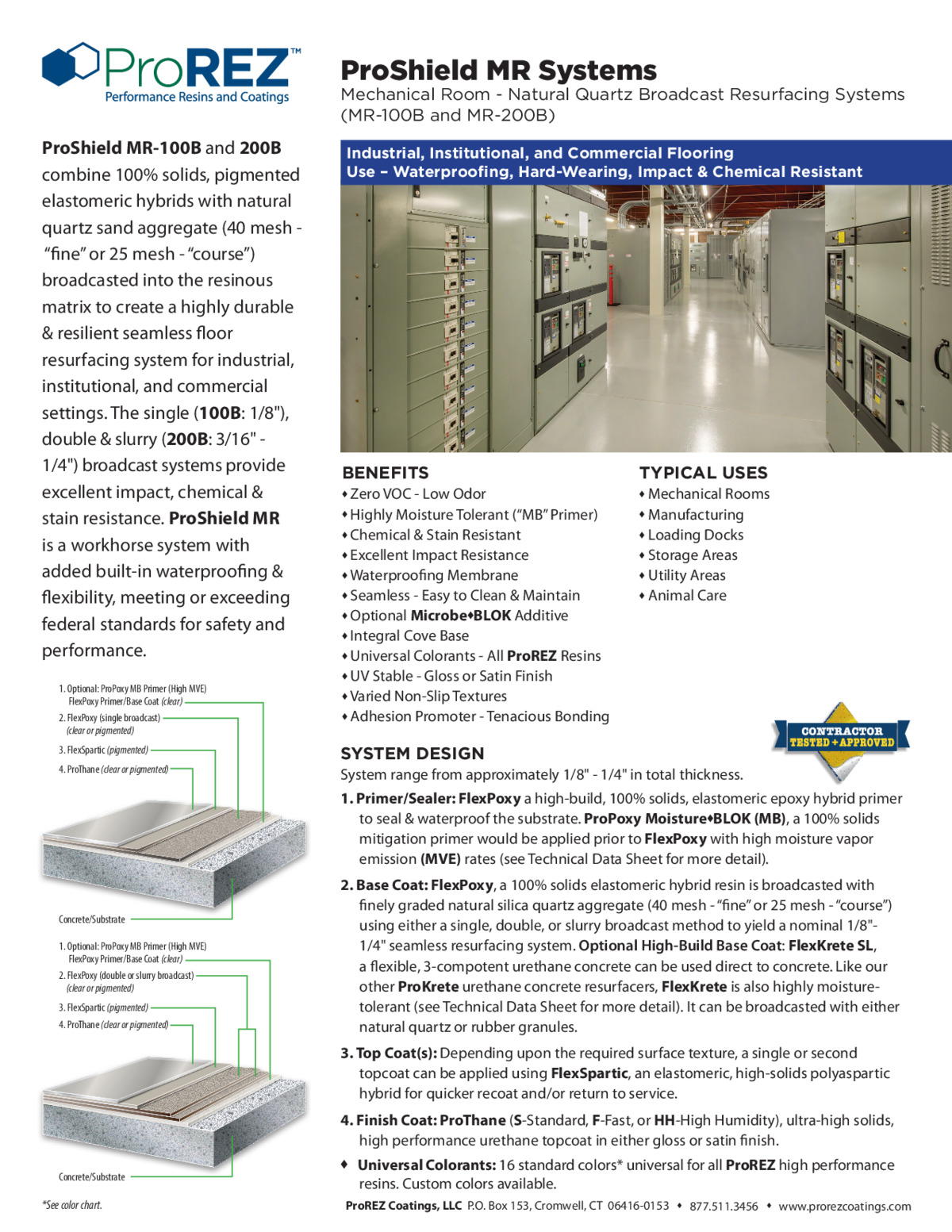

ProShield MR Systems Data Sheet

This system data sheet covers ProShield MR, a multi‑resin epoxy floor system formulated for medium to high chemical resistance and excellent abrasion performance. It begins by outlining the benefits—durable, easy to clean, and suitable for moderate to heavy traffic areas. Substrate preparation notes include shot blasting or diamond grinding to achieve an ICRI CSP 3–5 profile and verifying moisture levels. The document details mixing instructions for each resin coat (primer, base coat, top coat) and recommends sand broadcast for enhanced mechanical bond. Cure times (light foot traffic in 16 hours, full cure in 7 days) and performance properties (tensile, flexural, and compressive strengths) are provided. Installation guidance, coverage rates, and safety precautions close out the sheet.

View PDF

ProShield SF Systems Data Sheet

This system data sheet introduces ProShield SF-100B and SF-200B, 100% solids epoxy flooring systems broadcast with natural quartz aggregate for seamless, slip-resistant resurfacing. It begins by listing benefits such as low odor, UV stability, chemical resistance, and excellent durability under traffic and spills. The document outlines substrate preparation—diamond grinding or shot blasting to ICRI CSP 3–5 and ensuring moisture levels are within limits using an appropriate ProPoxy or MB primer. Mixing instructions cover blending ProPoxy resin with broadcasted quartz in single (1/16") or double (1/8"–3/16") layers, followed by pigmented epoxy or polyaspartic topcoats. A ProThane urethane finish coat (optional gloss or satin) completes the system. Finally, it provides options for mechanical rooms, slip-resistance additives, and compatibility with MicrobeuBLOK and integral cove base.

View PDF

ProClad ST System Data Sheet

This system data sheet describes ProClad ST, a trowel-applied, high-build epoxy mortar overlay system engineered for resurfacing worn concrete and protecting areas exposed to high abrasion, impact, and wet conditions. It begins by outlining key benefits such as chemical and stain resistance, moisture tolerance, and optional non-slip texture. The document details surface preparation—diamond grinding or shot blasting to ICRI CSP 3–5 with moisture-tolerant primers as needed—followed by mixing and placement of the epoxy mortar at a ¼″ to 1″ nominal thickness. ProClad ST can be finished with a ProPoxy grout coat and optionally sealed with ProThane or ProSpartic for added durability. The system also supports integral cove base installation up to 8″ and the use of MicrobeBLOK additive for hygienic applications.

View PDF

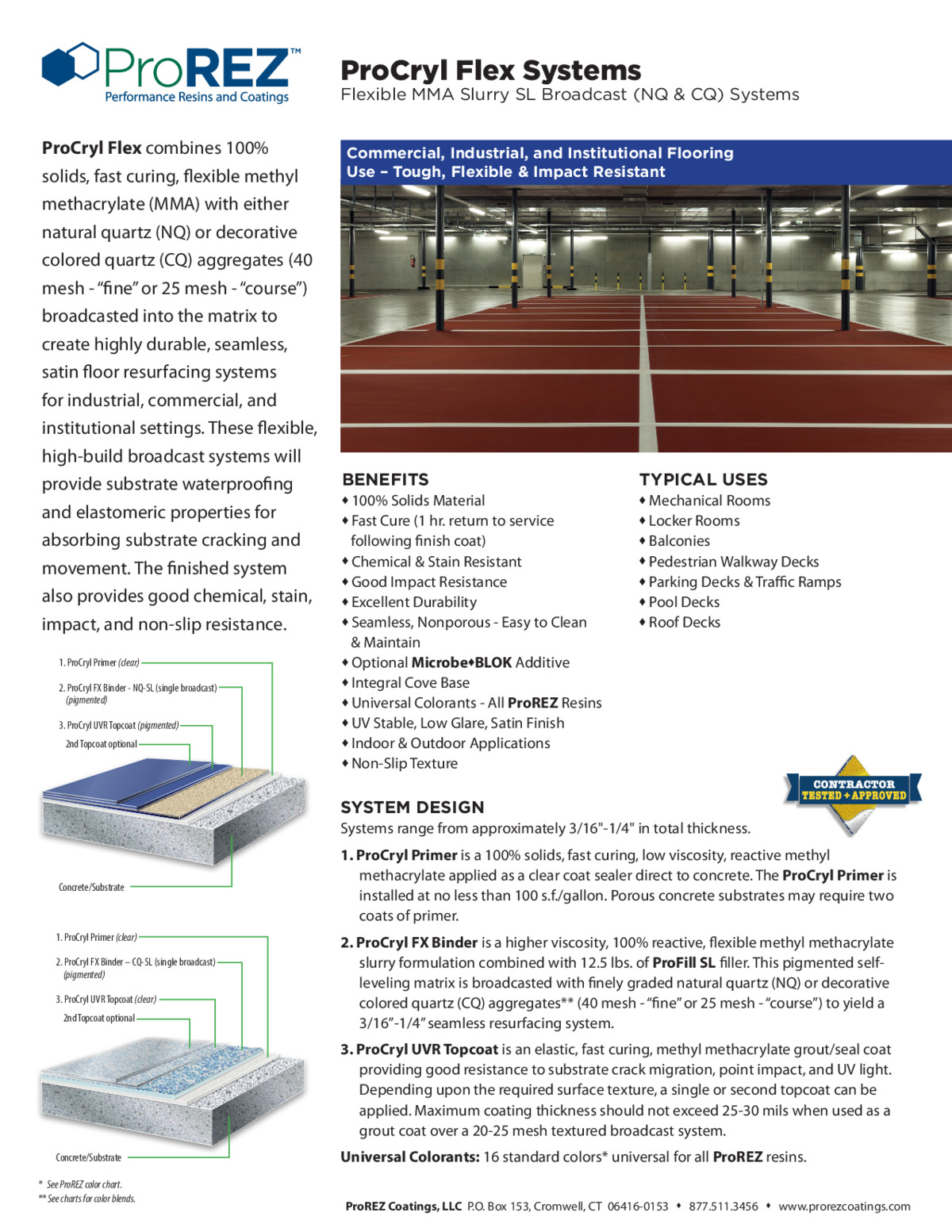

ProCryl Flex Deck System Data Sheet

This system data sheet covers ProCryl Flex Deck, a flexible MMA coating system designed for exterior decks, balconies, and other surfaces exposed to weather. It begins by listing benefits—UV stability, freeze/thaw durability, rapid cure (walkable in 1 hour), and seamless aesthetics. The document outlines substrate preparation—concrete or plywood surface profiling, moisture testing, and crack repair—followed by mixing ratios (resin to initiator) and application techniques (broadcast of colored quartz or vinyl flake followed by a UV‑stable topcoat). It provides performance data such as elongation (up to 150%), tensile strength, and chemical resistance to deicing salts. Finally, it includes recommended detail work for expansion joints, flashing, and perimeter conditions, plus safety guidelines for low‑odor MMA application.

View PDF

ProCryl CS System Data Sheet

This system data sheet describes ProCryl CS, a colored quartz broadcast MMA flooring system designed for decorative, slip‑resistant surfaces. It begins by highlighting benefits—100% solids MMA binder, rapid cure (1 hour to service), UV stability, and customizable quartz color blends. The document outlines substrate preparation—diamond grinding to ICRI CSP 3–5 and moisture vapor emission limits—followed by mixing instructions and quartz broadcast rates (e.g., 1–1.5 lb/ft²). A clear UV‑resistant topcoat is then applied to seal the quartz. Finally, it provides performance properties such as tensile strength, abrasion resistance, and chemical resistance, plus recommended film thicknesses and cure times under various temperatures.

View PDF

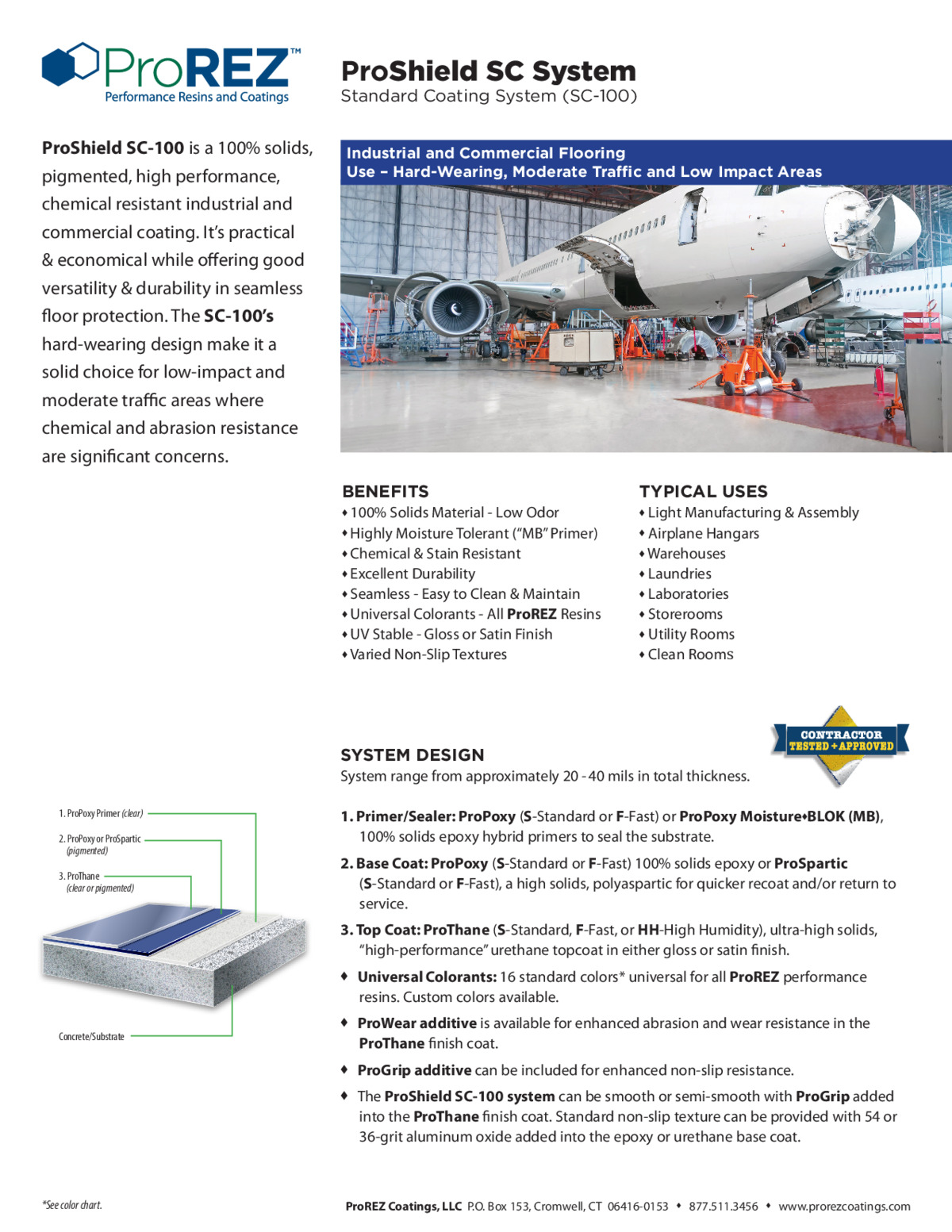

ProShield SC 100 System Data Sheet

This system data sheet details ProShield SC 100, a solvent‑based epoxy floor coating engineered for heavy‑duty chemical and solvent resistance. It begins by listing benefits—excellent resistance to petroleum, solvents, and corrosive chemicals, plus high adhesion to concrete. The document outlines substrate preparation—shot blasting or diamond grinding to ICRI CSP 3–5 and ensuring proper moisture vapor emission control. Mixing instructions cover the epoxy resin and curing agent ratios, followed by recommended application methods—brush or roller for three coats to achieve a final film thickness of 15–20 mils. Performance data such as tensile strength, flexural modulus, and chemical spot test results are provided, along with cure times (tack free in 8 hours, full chemical cure in 7 days). Safety and handling precautions for solvent‑based epoxies conclude the sheet.

View PDF