ProPOXY LWT

PROPOXY LWT

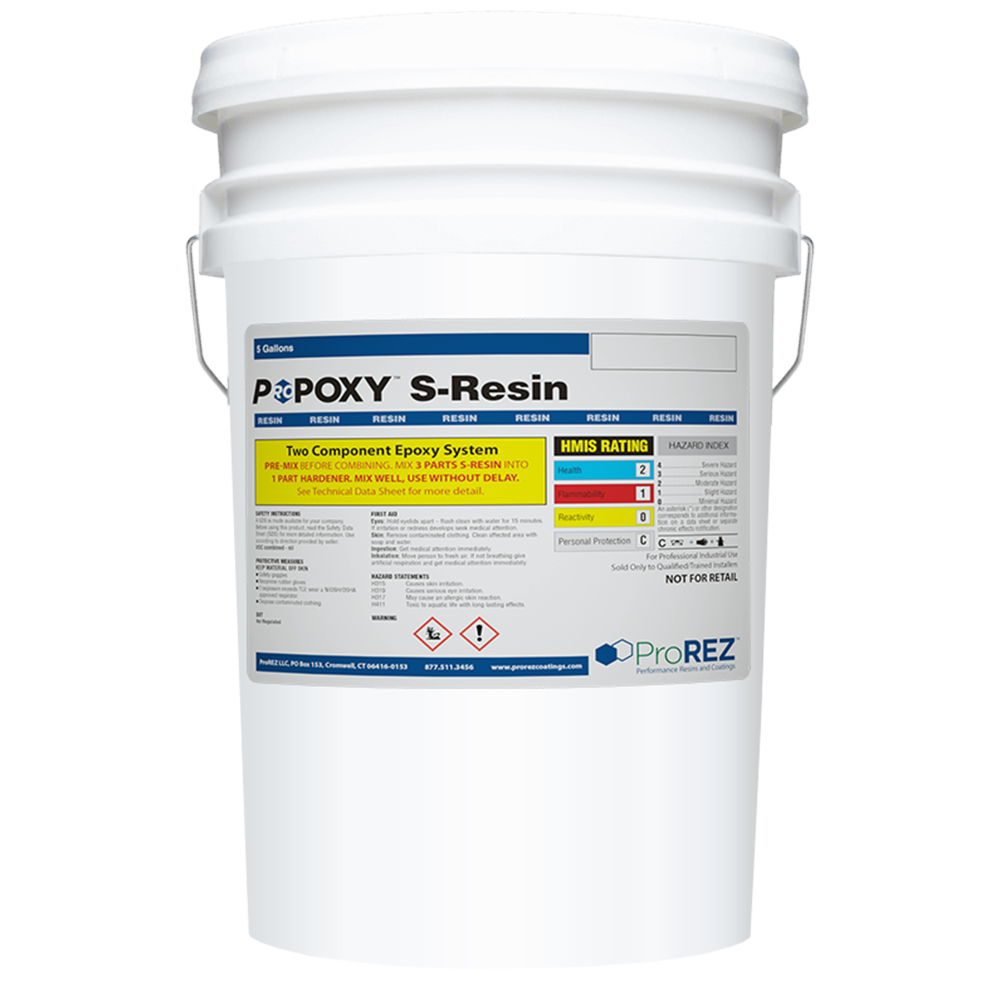

ProPOXY LWT is a long working time version of the ProPOXY 3:1 epoxy coating system, engineered for projects requiring extended application windows. It combines ProPOXY S Resin with the LWT-Hardener to deliver a slower curing, high-performance coating suited to ProLumina systems or large surface areas. This low odor, 100% solids system is compliant with USDA, FDA, and EPA VOC standards. The mix ratio is 3 parts resin to 1 part hardener, with optional field tinting using ProColor Universal Colorants. Applications include clean rooms, laboratories, and commercial spaces where additional working time is necessary for precision or coverage.